Categorys

Hot Product

AC 5 axis CNC Water Jet Cutting Machine

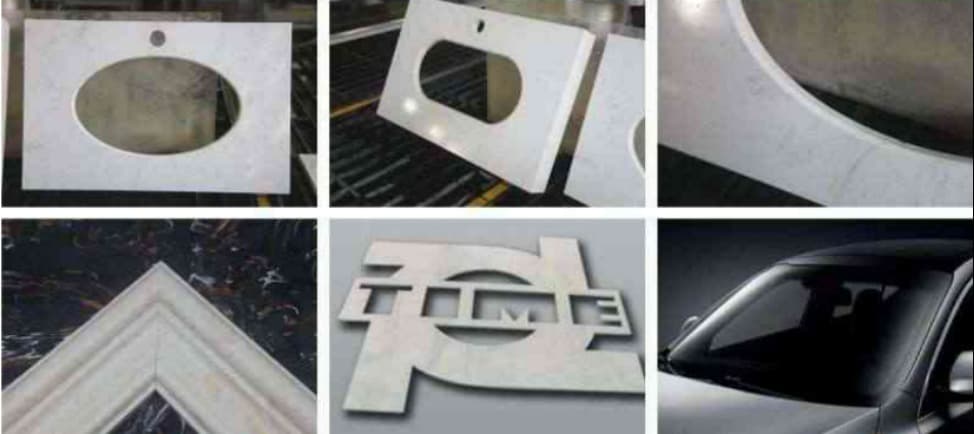

Waterjet cutting is remarkable, and waterjet cutting machines can be used in aerospace, automotive manufacturing, electronics, stone processing, and many other industries. Materials typically cut with waterjets include textiles, rubber, composites, stone, tile, glass, etc. Most ceramics can also be cut on a porcelain cutting waterjet.

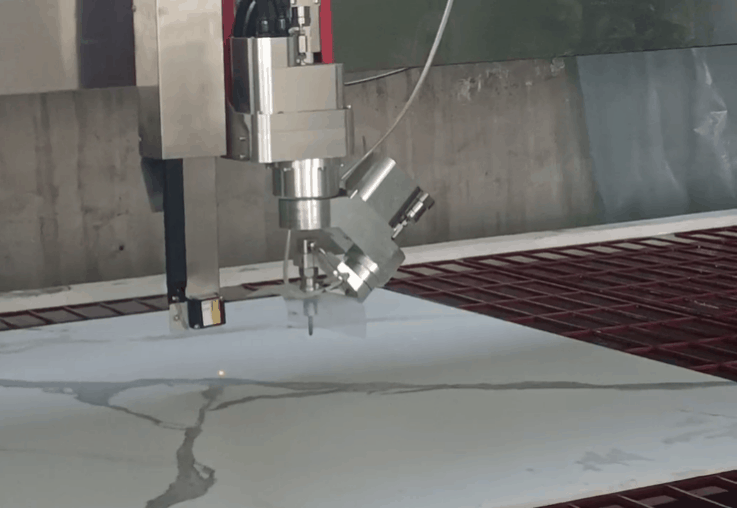

Advantages of AC 5 axis CNC waterjet head:

(1) 5 axis CNC waterjet cutting machine adopts AC axis design, real 5 axis (X. Y. Z. A.C) move.

(2) Structure more tight for the Waterproof and dustproof. electrical wiring has a tidier and more clear layout.

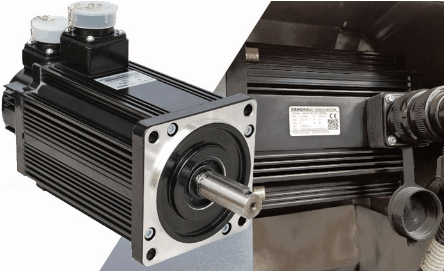

(3) 5 axis CNC waterjet cutter adopts international high-end brand servo motor and servo driver to make the control accuracy higher.

(4) Reasonable design, evenly the force, effectively improve the water jet operating life and reliability.

Main Features

(1) Processable any curve cutting, flexible, convenient and versatile.

(2) Notch is fast and smooth, no dust, no thermal deformation and no pollution.Tension-free processed parts due to minimal cutting force.

(3) Narrow kerf – The amount of material removed by the water jet stream is typically about 0.5-1.0 mm wide. Cut width optimizes material use, increasing cost effectiveness.

(4) Cut Recovery - Pick back up where Jet stopped.

(5) Programmable Z axis height. Z axis retracts between pierces.

(6) Servo motor, linear sledge and vehicles, helical rack and pinions is used for providing a rapid and smooth axial movement.

(7) High-Performance drive system, which permit high-precision production of parts as well as the highest processing speed.

(8) Driver system sealed against water,dust and grit. Long working life.

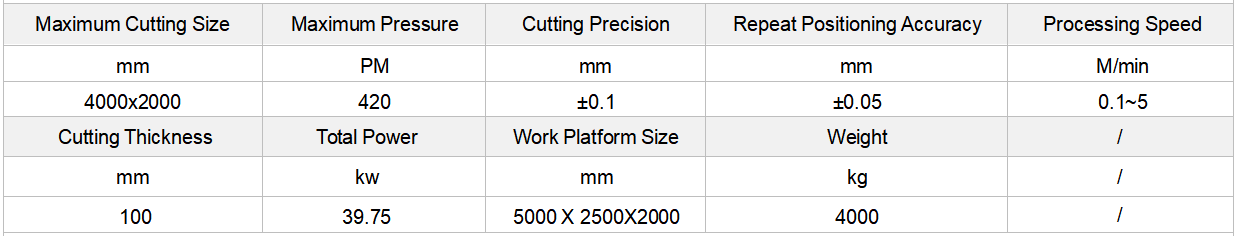

Equipment parameters

Application

* Stone/Ceramic industries such as used for countertops, art puzzles, flooring Inlays and mosaics.

* Glass industry , such as bathroom glass, shop window glass, automotive glass and appliance glass.

* Metal industries such as Decoration, decoration in the stainless steel and other metal cutting process, equipment cover cutting, Cutting of metal parts.

* Gasket Cutting

* Foam Product Cutting.

Main Equipment Description

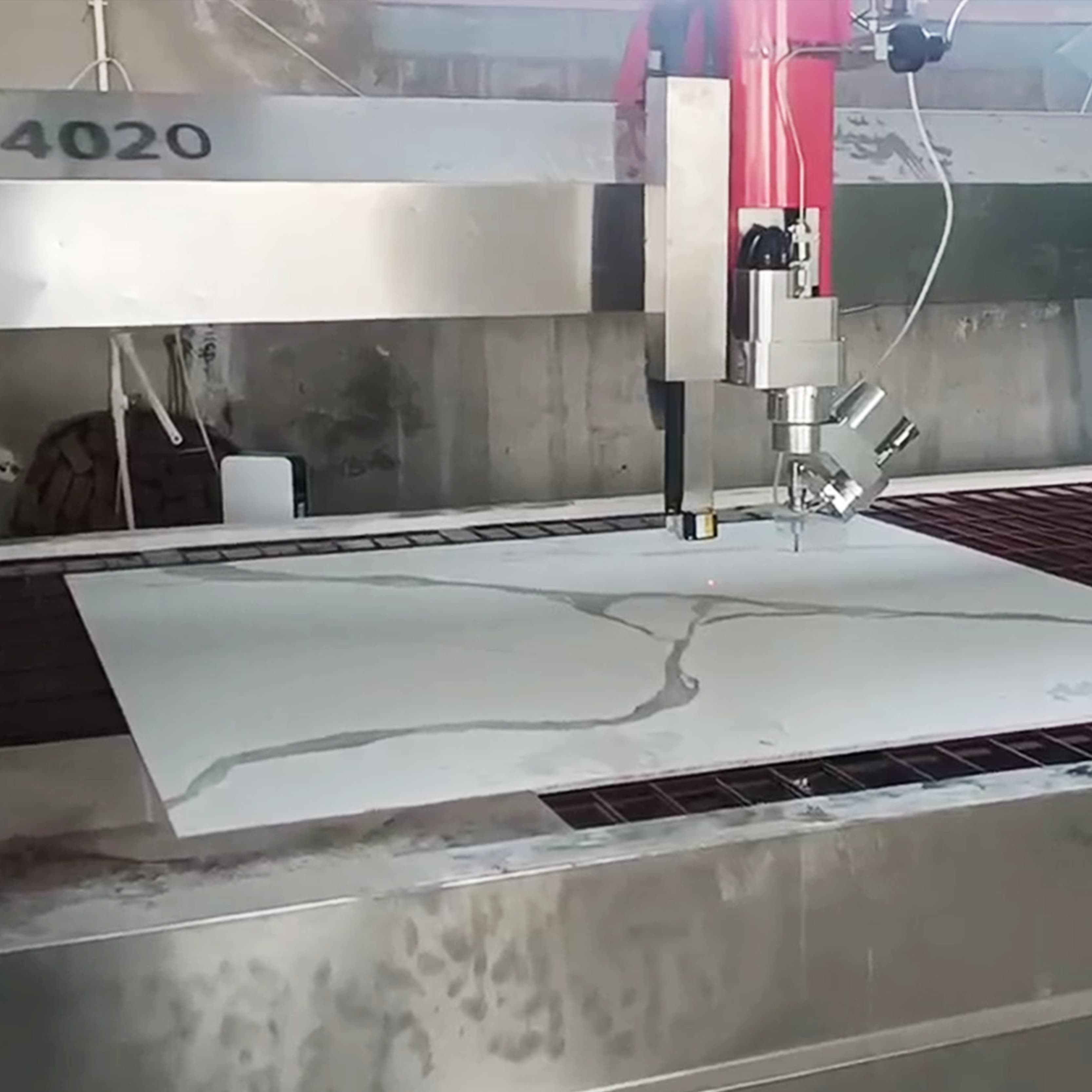

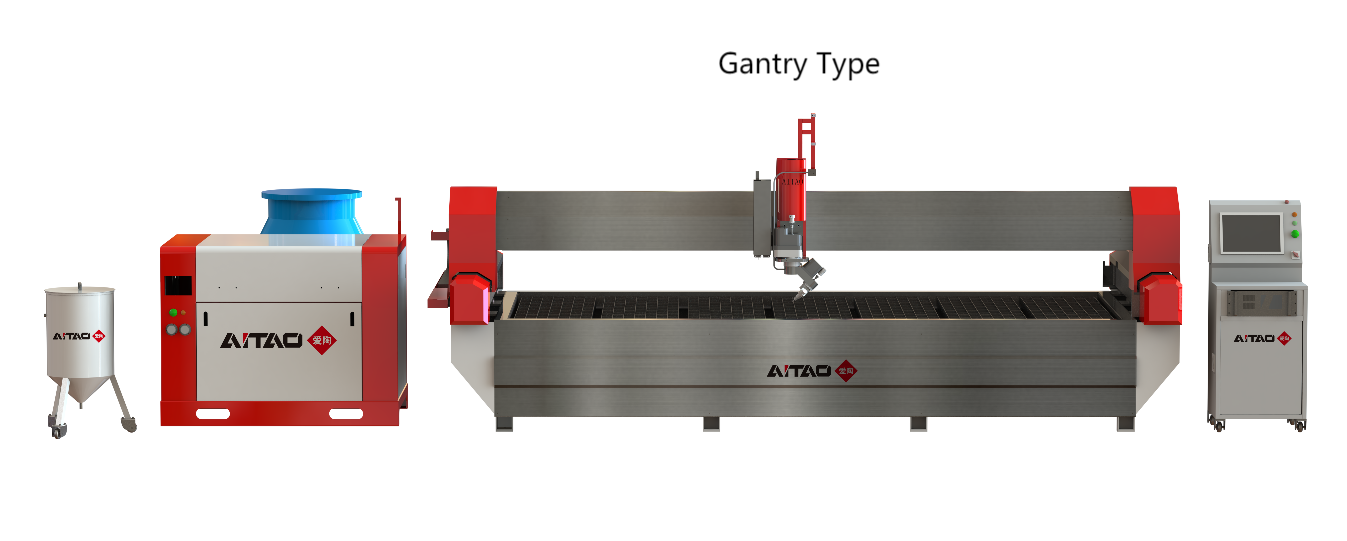

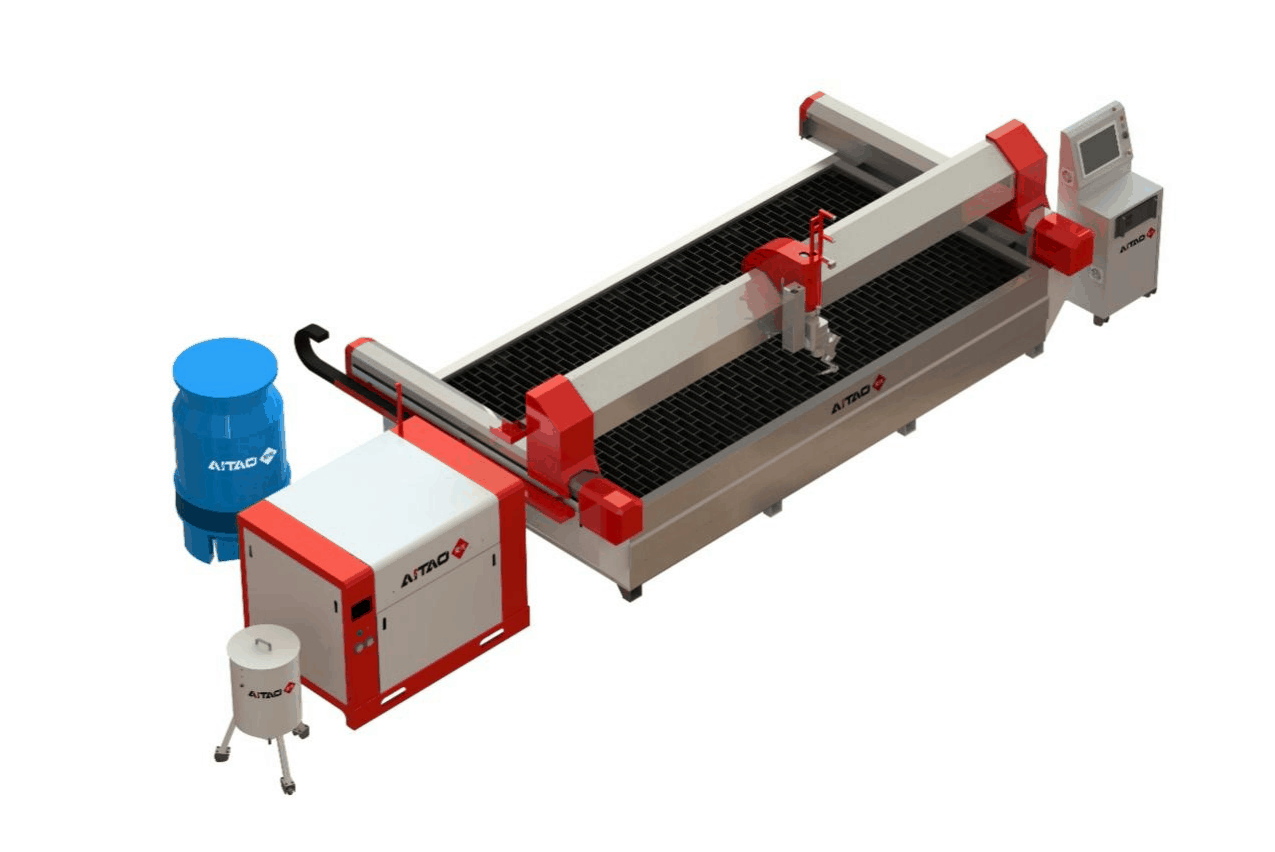

cutting platform specifications

AT3020:3000x2000(mm)

AT4020 : 4000x2000(mm)

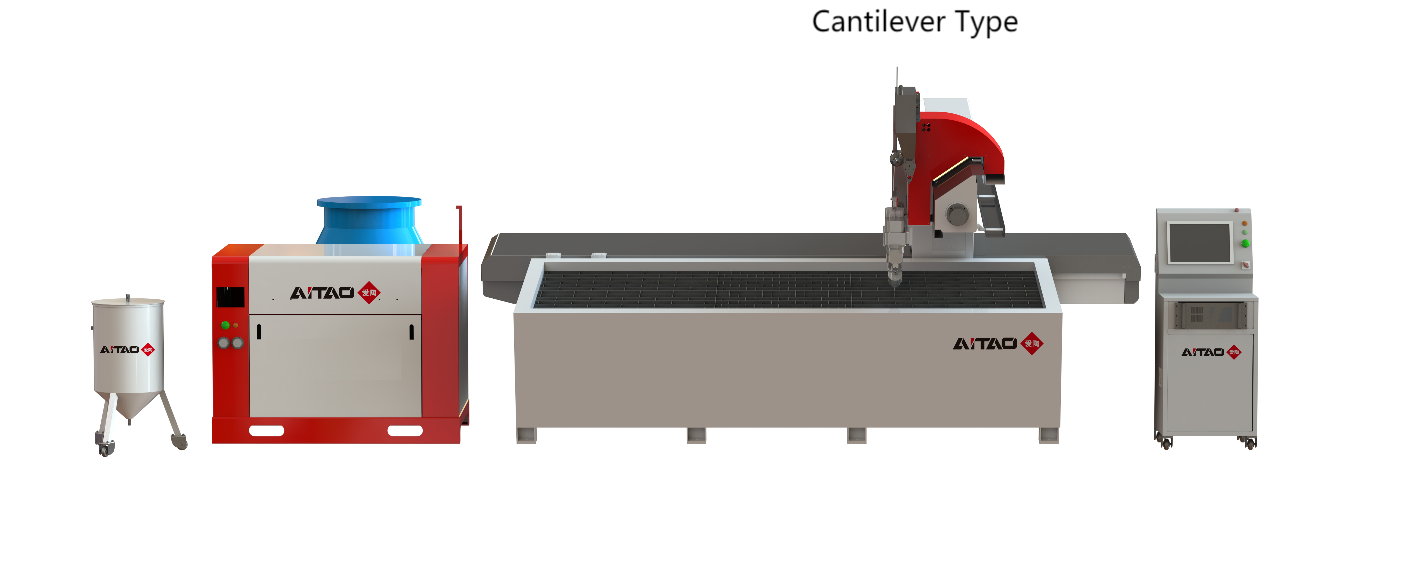

Cantilever cutting platform specifications:

AT2515:2600 x 1600(mm) AT3015:3100 x 1600(mm)

Cutting accuracy: ± 0.1mm

Repetitive accuracy: ± 0.05

Moving parts: Taiwan "ABBA" or "TBI"

Linear guide rail/ball screw "oil bubble type

X-axis running speed: 0-5000mm/min; 1.5KW

Y-axis running speed: 0-5000mm/min; 1.5KW

Z-axis running speed: 0-1000mm/min; 0.40KW

A-axis rotation angle: ± 70 degrees; 0.20KW

C-axis rotation angle: infinite; 0.20KW

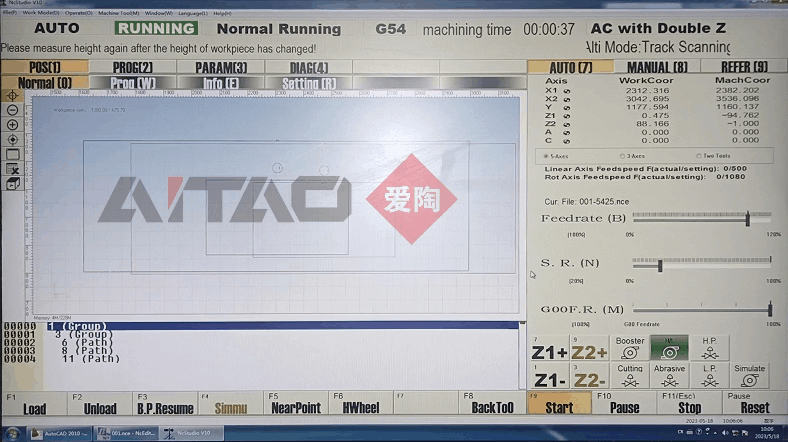

Control system:CNC driver;

Industrial control computer; JAWJ cutting software (NC Studio V-9.38)

Based on Win7 32-bit, genuine Shanghai Naikai Ncstudio

Operation interface: Chinese/English can be switched freely

Z-axis stroke: 110mm

Centralized lubrication system makes machine tool operation more reliable

Servo motor: Weizhi AC servo

Power supply: 220V/380V/50HZ

|

model |

AT420 |

AT420Ⅱ |

AT450 |

|

Max.pressure :(Mpa) |

420 |

420 |

380 |

|

Long time working pressure:(Mpa) |

280-380 |

280-380 |

280-380 |

|

Intensifier ratio :(L/min) |

1:20 |

1:20 |

1:20 |

|

Max.flow rate :(L) |

3.7 |

4.6 |

6.8 |

|

Inlet pressure :(Mpa) |

0.4 |

0.6 |

0.6 |

|

Max.rifice size :(mm) |

0.33 |

0.35 |

0.35 |

|

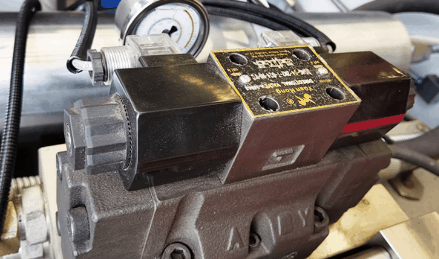

Max.pump flow :(L/min) |

105 |

148 |

148 |

|

Max.pump pressure : (Mpa) |

31.5 |

31.5 |

31.5 |

|

Max.pump pressure : (L) |

120 |

120 |

120 |

|

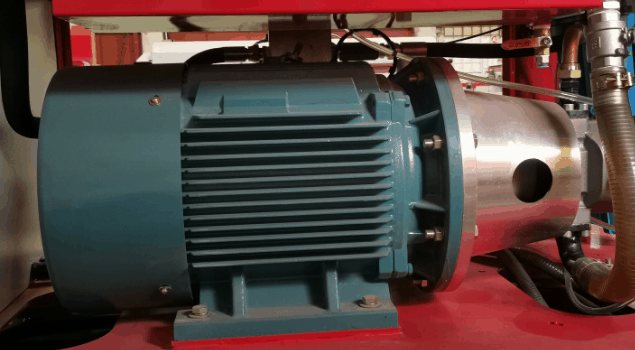

Power supply : (Kw) |

30-37 |

37-45 |

37-45 |

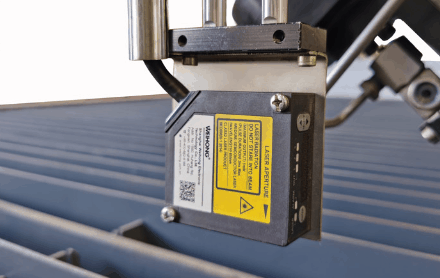

The automatic sand supply system uses air pressure to deliver sand from the water knife to the cutting head

Inside the small sand bucket, which reduces the labor intensity of operators, and there is no need to stop the machine when adding sand,

Improved work efficiency and reflected the automation level of CNC water jet knives.

Introducing international advanced technology and designing according to international safety standards, ensuring safety and reliability.

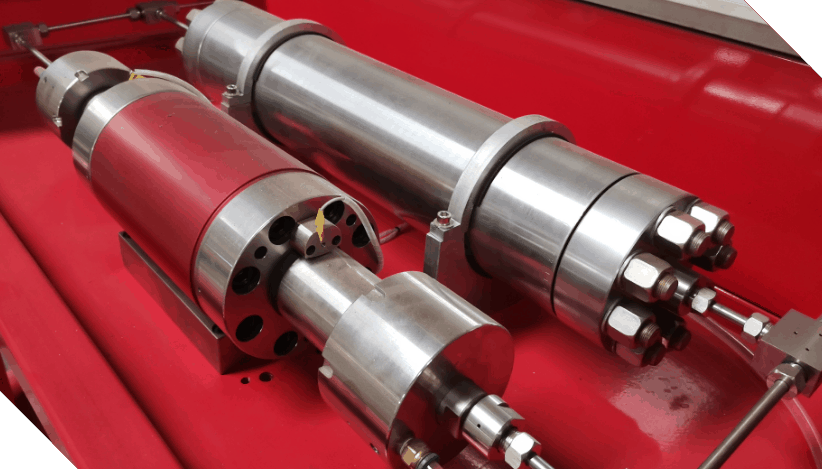

Detail Images

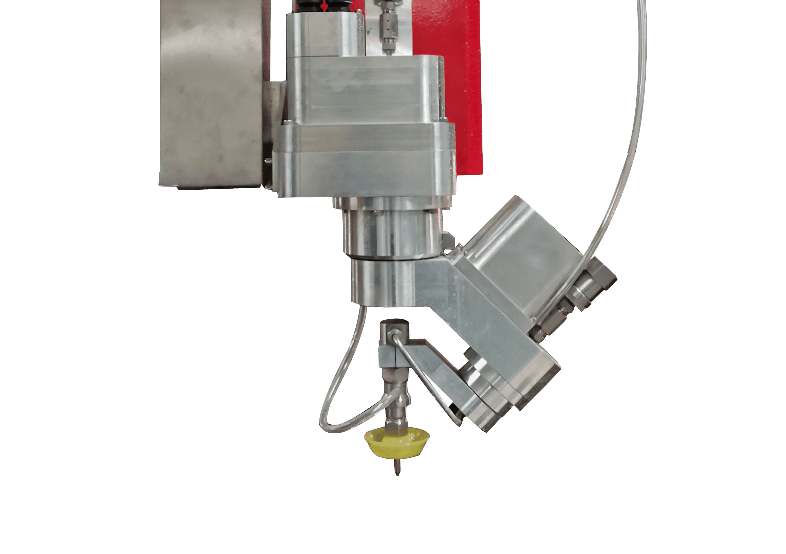

AC Five Axis Cutting System

The Aitao five axis water jet cutting system has added an A-axis (winding) on top of the standard three axis (XYZ)X-axis rotation) C-axis rotation (around Z-axis rotation) can achieve large angle deflection, with a maximum deflection angle of up toThe travel of the 75 Z axis is equivalent to that of a standard water jet.

Our Service

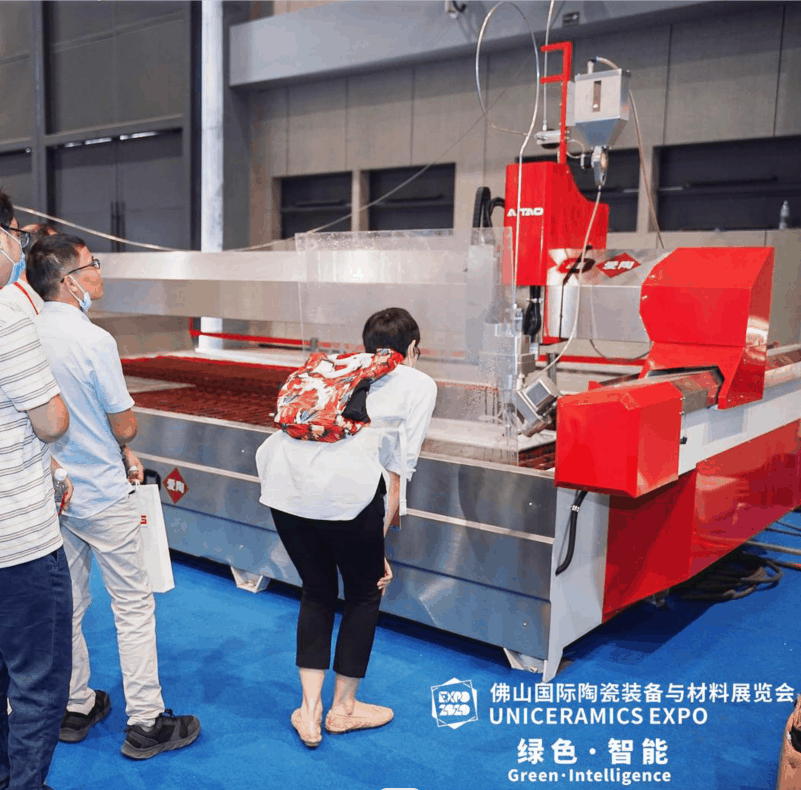

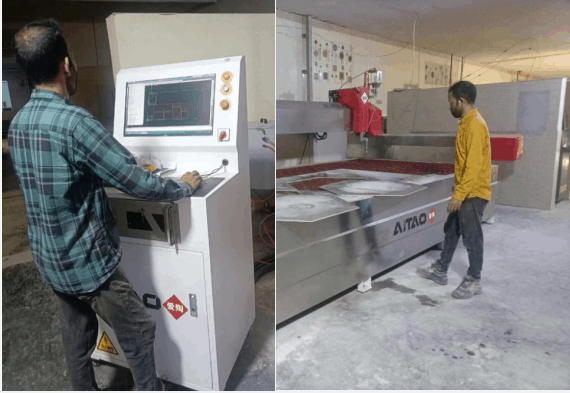

Equipment Cases