Computer Numerical Control (CNC) machines have revolutionized manufacturing processes by providing precision and efficiency. Among the various CNC machines available, the 4-axis and 5-axis systems stand out for their ability to handle complex machining tasks. To shed light on the capabilities and uses of 4-axis- and 5-axis CNC machines, we shall examine their main distinctions in this article.

What Are The 4-Axis CNC Machines?

A 4-axis CNC machine is characterized by its ability to move along four axes: X, Y, Z, and one additional rotational axis. The rotational axis is typically referred to as the A-axis. The workpiece may be rotated on the A-axis, which eliminates the need for human repositioning during multi-side milling. This extra axis increases the machine's adaptability and suitability for a range of uses.

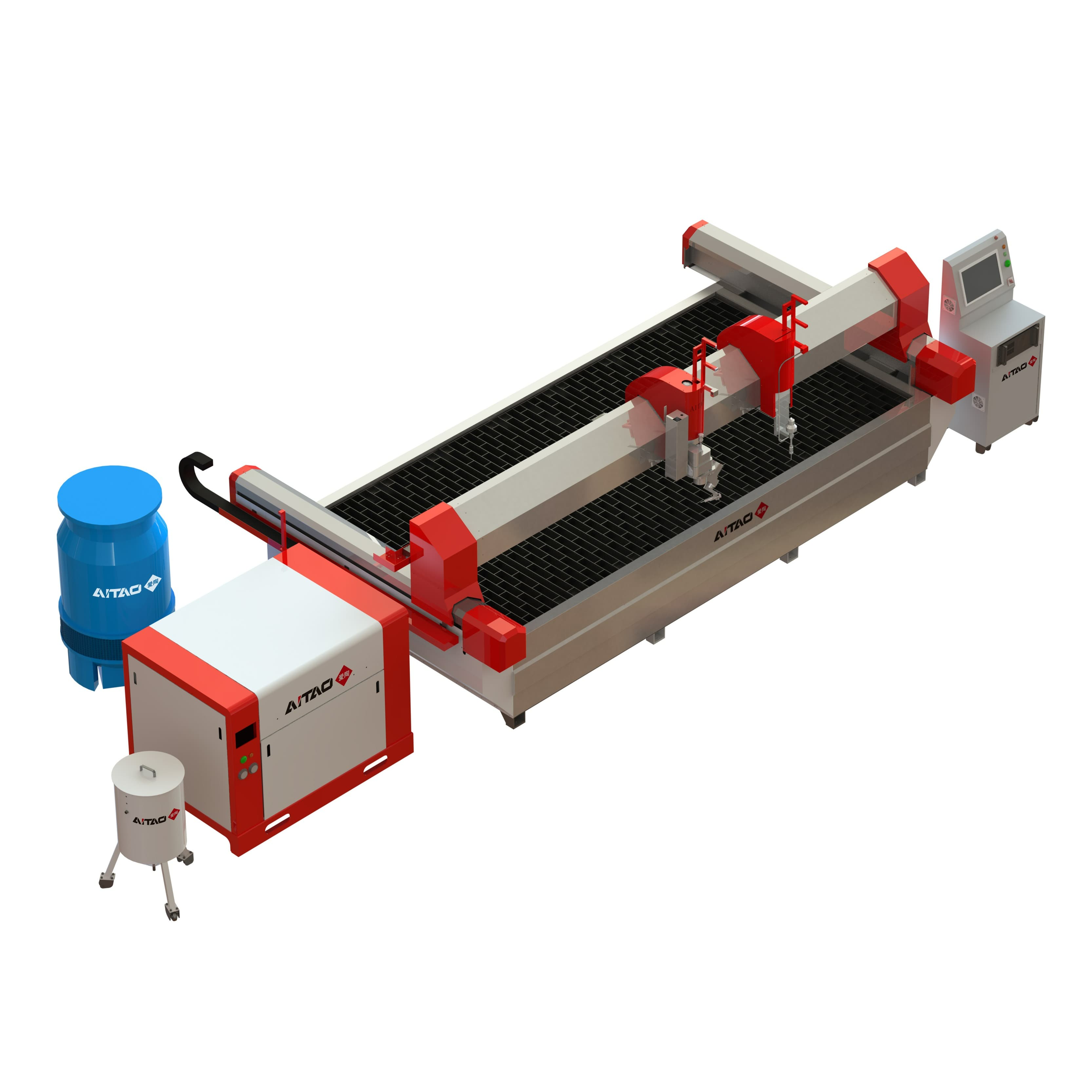

Automatic CNC Bridge Saw For Sale

Key Features And Applications Of 4-Axis CNC Machines

Enhanced Efficiency In Production

Rotational Axis (A): The addition of the A-axis allows for the rotation of the workpiece, reducing the need for manual repositioning. This feature allows for uninterrupted continuous machining, which greatly improves manufacturing process efficiency.

Complex Contouring Capability

Multi-Angle Machining: four-axis CNC machines are skilled at producing intricate shapes and complicated forms. The ability to approach the workpiece from different angles ensures that even the most intricate geometries can be accurately machined with a high level of precision.

Versatility in Mold and Die Making

Mold and Die Production: The versatility of 4-axis machines makes them particularly well-suited for the mold and die-making industry. Because the rotary axis makes it easier to machine complicated surfaces and forms, manufacturers can create complex molds and dies more quickly and effectively.

Improved Surface Finish

The ability to continuously machine a workpiece's numerous sides without having to realign the workpiece is made possible by the A-axis, which enhances surface finish and component quality overall.

Cost-Effective Solution

Balanced Performance: Because they combine cost-effectiveness and adaptability, 4-axis CNC machines are the favored option for companies that demand a moderate level of complexity but do not require the advanced capabilities of 5-axis machines.

What Are The 5-Axis CNC Machines?

In comparison, 5-axis CNC machines possess an additional rotary axis, typically labeled as the B-axis. This axis allows the machine to tilt the workpiece, providing even greater flexibility and maneuverability. These machines may approach the workpiece from almost any angle because of their five axes of motion (X, Y, Z, A, and B).

Key Features And Applications Of 5-Axis CNC Machines

Complete Machining in a Single Setup

Two Rotational Axes (A and B): The workpiece may be tilted and rotated with 5-axis CNC machines since they have both A and B axes. This capability allows for machining from various angles in a single setup, reducing the need for multiple clamping and repositioning.

Reduced Setup Time And Increased Precision

Minimized Workpiece Handling: 5-axis CNC machines minimize the need for manual intervention and repositioning, leading to a significant reduction in setup time. The finished machined product has increased precision and accuracy as a consequence.

Ideal For Aerospace And Medical Industries

Complex Components: The ability to approach the workpiece from any angle makes 5-axis machines indispensable for industries such as aerospace and medical manufacturing. These sectors frequently work with extremely complicated and detailed parts that require accurate multidirectional machining.

Optimized Tool Paths for Efficiency

Continuous Tool Paths: 5-axis machines can optimize tool paths, ensuring that the cutting tool maintains optimal contact with the workpiece throughout the machining process. This function helps to increase overall productivity and remove material efficiently.

Enhanced Flexibility For Prototyping

Prototyping And Customization: 5-axis CNC machines are well-suited for prototyping and the production of custom components. It is easier to create original and intricate designs when a workpiece may be approached from many perspectives, giving designers and engineers more creative freedom.

Distinguishing Factors between 4-Axis and 5-Axis CNC Machines

The 4-axis and 5-axis CNC machines are noteworthy developments in manufacturing technology, with unique characteristics meeting certain industry requirements in each case. The primary differentiator lies in the number of rotational axes. A 4-axis CNC machine maneuvers along X, Y, and Z axes, and one rotational axis (A-axis), facilitating multi-sided machining without complex tilting.

On the other hand, 5-axis CNC machines, with the addition of a second rotational axis (B-axis), introduce a new dimension of complexity. This capability allows the workpiece not only to rotate but also to tilt, enabling machining from multiple angles in a single setup. 5-axis machines are more precise and versatile, which is important for complex and three-dimensional components, and are beneficial to industries including aerospace and medical manufacture. In the end, the decision between the two is based on the particular needs of the production process, component complexity, and financial constraints.

Conclusion

The choice between the two depends on the complexity of the parts to be machined, production requirements, and the desired level of precision. As a premier cutting machine factory, AITAO specializes in producing various cutting machines, not only CNC machines but also waterjet machines. Choose the innovation and quality of AITAO for your industry-cutting solutions. Contact us today to learn more about our products and how they can benefit your business.