In the bustling world of construction and design, CNC (Computer Numerical Control) technology has been nothing short of a game-changer, especially when it comes to working with stone. Gone are the days when "machine cut stone" was just a buzzword—now, it's the gold standard that industry insiders swear by. Let's dive into the six unbeatable benefits of using CNC for cutting stone, which have made it the darling of architects and designers alike.

Precision And Accuracy

Imagine being able to turn your most intricate design dreams into reality, down to the last millimeter—that's the magic of CNC stone cutting. It's like having an artist who never tires and a craftsman who never errs, all rolled into one. CNC brings a level of precision to the table that's nothing short of revolutionary, making those complex architectural projects seem like a walk in the park.

Consistency In Quality

Remember the frustration when you'd get stone pieces that were more like distant cousins than identical twins? CNC puts an end to that gamble. Each piece is a carbon copy of your design, ensuring that when it comes to fitting them together, it's as seamless as a well-rehearsed dance routine.

Complex And Intricate Designs

CNC technology has opened a Pandora's box of possibilities for stone designs. It's like having a genie at your disposal—one that grants you unlimited wishes to experiment with intricate patterns and sophisticated engravings that manual methods wouldn't dare touch.

Time Efficiency

CNC machine-cutting significantly reduces the time required to process stone materials. The automation of cutting processes means that multiple pieces can be cut simultaneously, and the machinery operates around the clock, minimizing downtime. This speedier manufacturing process results in faster project completion timeframes and increased overall efficiency.

Reduced Waste

Traditional stone-cutting methods often resulted in substantial material wastage due to the imprecise nature of manual cutting. CNC technology optimizes the cutting process, minimizing material wastage and reducing the need for excessive raw materials. This not only saves money, but it also conforms with sustainable practices by preserving natural resources.

Enhanced Safety

CNC machine-cut stone reduces the need for manual labor in cutting processes, consequently minimizing the risk of accidents and injuries associated with traditional stone-cutting methods. Workers are not exposed to potentially hazardous cutting equipment, making the workplace safer.

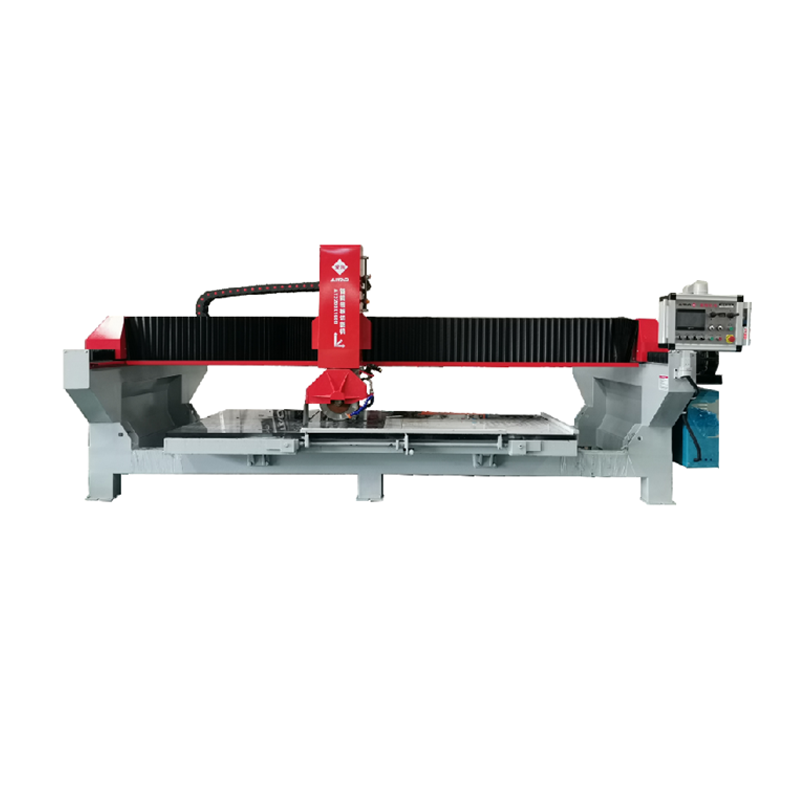

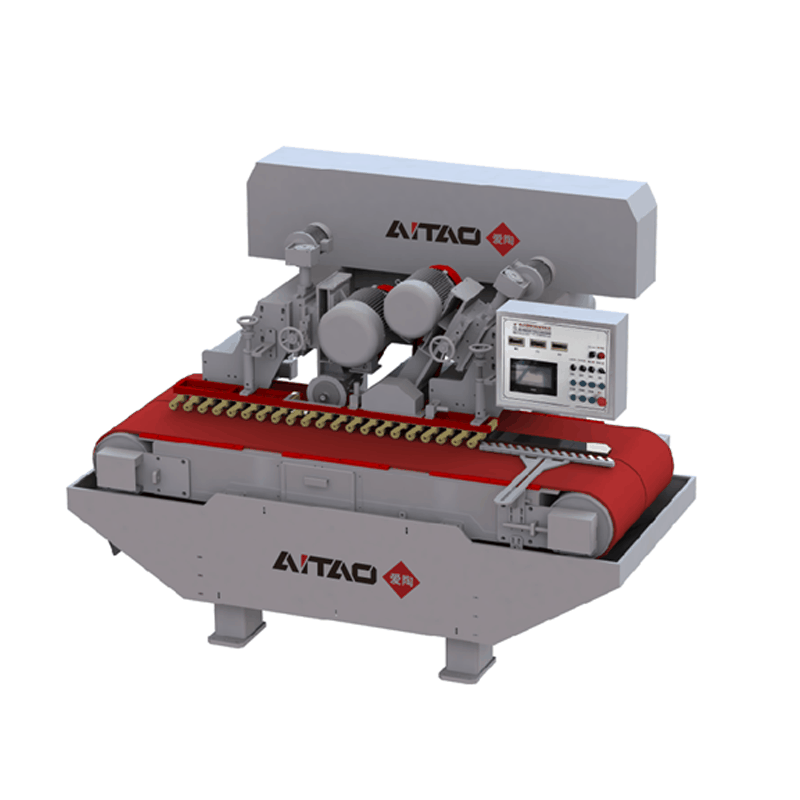

Stone Slab Cutting Machine Suppliers

Technology Integration and Customization

Embracing the digital era, the integration of advanced software with CNC stone cutting machinery allows for unparalleled customization. Clients seeking 'machine cut stone' can now specify dimensions, patterns, and finishes with confidence, knowing that the 'cnc stone cutting' process can be tailored to their exact requirements. This synergy of technology and craftsmanship ensures that every piece of stone is not only aesthetically pleasing but also perfectly suited to its intended application.

Scalability And Replicability

CNC technology allows for the rapid replication of designs across a large number of stone pieces. This scalability is crucial for projects that require a consistent design motif throughout various elements. Whether it's duplicating complicated patterns on a large facade or making similar decorative items, CNC machine-cut stone provides unrivaled efficiency.

Conclusion

The leap to CNC machine-cut stone isn't just a step forward—it's a giant leap for the industry. It's not just about keeping up with the times; it's about setting the pace for the future. As we continue to push the boundaries of what's possible with stone, CNC technology will be right there, leading the charge.

Experience the CNC Difference with AITAO

Ready to see what CNC can do for your next project? At AITAO, we're not just riding the wave of innovation; we're making the waves with our top-notch CNC stone cutting technology. Reach out and let us show you how our solutions can transform your next project from ordinary to extraordinary.

FAQs

1. What is CNC Stone Cutting and How Does It Differ from Traditional Methods?

CNC stone cutting utilizes advanced computer numerical control technology to carve, shape, and cut stone with extreme precision. Unlike traditional stone cutting, which relies on manual labor and can be inconsistent, CNC stone cutting is automated, resulting in uniform pieces with intricate designs that are replicated perfectly every time. This method not only saves time but also reduces material wastage, making it a more efficient and eco-friendly option.

2. Can CNC Stone Cutting Machines Handle Different Types of Stone Materials?

Yes, CNC stone cutting machines are versatile and can work with a wide range of stone materials, including granite, marble, limestone, and more. The technology allows for adjustments in the cutting process to accommodate the hardness and density of different stones, ensuring that each type is cut with the appropriate technique to maintain the integrity of the material.

3. Are Custom Designs Possible with CNC Stone Cutting?

Absolutely! One of the significant advantages of CNC stone cutting is the ability to create custom designs with high precision. Whether you're looking to incorporate complex geometric patterns, detailed imagery, or unique textural finishes, CNC machines can be programmed to achieve the specific artistic vision or functional requirement of any project.