In the cutting-edge realm of fabrication and manufacturing, the 5-axis waterjet cutting machine stands as a pinnacle of innovation, merging high-pressure waterjet technology with advanced 5-axis controls to deliver unmatched precision and versatility. This article delves into the myriad of advantages of waterjet cutting, highlighting why the 5-axis waterjet machine is an indispensable tool in modern production environments.

Precision and Complexity in Waterjet Cutting

The 5-axis waterjet cutting machine redefines accuracy with its unparalleled precision in every cut. Standing out from conventional methods such as plasma or laser, the 5-axis waterjet operates without generating heat, sidestepping any potential for heat-related distortions, warping, or melting. This cold-cutting advantage ensures that every incision is remarkably exact, meeting the stringent requirements of sectors demanding complex geometries and strict tolerances, like the aerospace and medical industries.

Material Versatility with 5-Axis Waterjet Technology

The 5-axis waterjet cutting machine excels in its ability to slice through an extensive portfolio of materials with unmatched ease. Whether it's metals, composites, rubber, plastics, ceramics, or stone, the 5-axis waterjet adapts seamlessly without the need for tool changes or concerns about heat-affected zones. This versatility empowers manufacturers to tackle diverse projects with a single machine, streamlining operations and reducing the need for multiple specialized cutting systems.

Mastering Complex Geometries with 5-axis Waterjet Cutting

Where traditional 2D cutting falls short, the 5-axis waterjet cutting machine thrives, effortlessly navigating the realm of complex 3D geometries. The dynamic tilting of the cutting head allows for the creation of bevels, chamfers, and intricate contours, offering a perfect solution for industries such as automotive and architecture that frequently require sophisticated and detailed cuts.

Waterjet Cutting For Ceramic Tile Packaging Line

Minimizing Waste with High-Precision Waterjet Cutting

The 5-axis waterjet's precision is not just about accuracy; it's also about sustainability. By delivering precise cuts and optimizing material utilization through advanced nesting capabilities, these machines significantly reduce scrap. This efficiency translates to cost savings and a reduced environmental footprint, a crucial consideration in sectors dealing with costly or scarce materials.

Enhanced Speed and Productivity in Waterjet Operations

Efficiency goes hand-in-hand with the precision of 5-axis waterjet machines. Capable of swift cutting speeds, these machines are ideal for high-volume production settings. The reduction or elimination of post-processing steps, such as deburring and grinding, further bolsters productivity and shortens overall project lead times.

Waterjet Applications In Ceramic Tile Cutting

Eco-Friendly Cutting with 5-Axis Waterjet Technology

The 5-axis waterjet cutting process stands out for its eco-conscious approach. It produces minimal hazardous emissions and waste, and the water utilized can frequently be treated and reused. The cold-cutting technique also means less energy consumption, aligning with sustainability goals by reducing the carbon footprint of manufacturing operations.

Enhancing Workplace Safety with 5-Axis Waterjet Machines

The operation of 5-axis waterjet machines inherently promotes a safer workplace. The absence of heat generation and hazardous emissions significantly reduces the risk of accidents from sparks or chemical exposures. This safety feature makes the 5-axis waterjet a preferred choice for businesses prioritizing the well-being of their workforce.

Conclusion

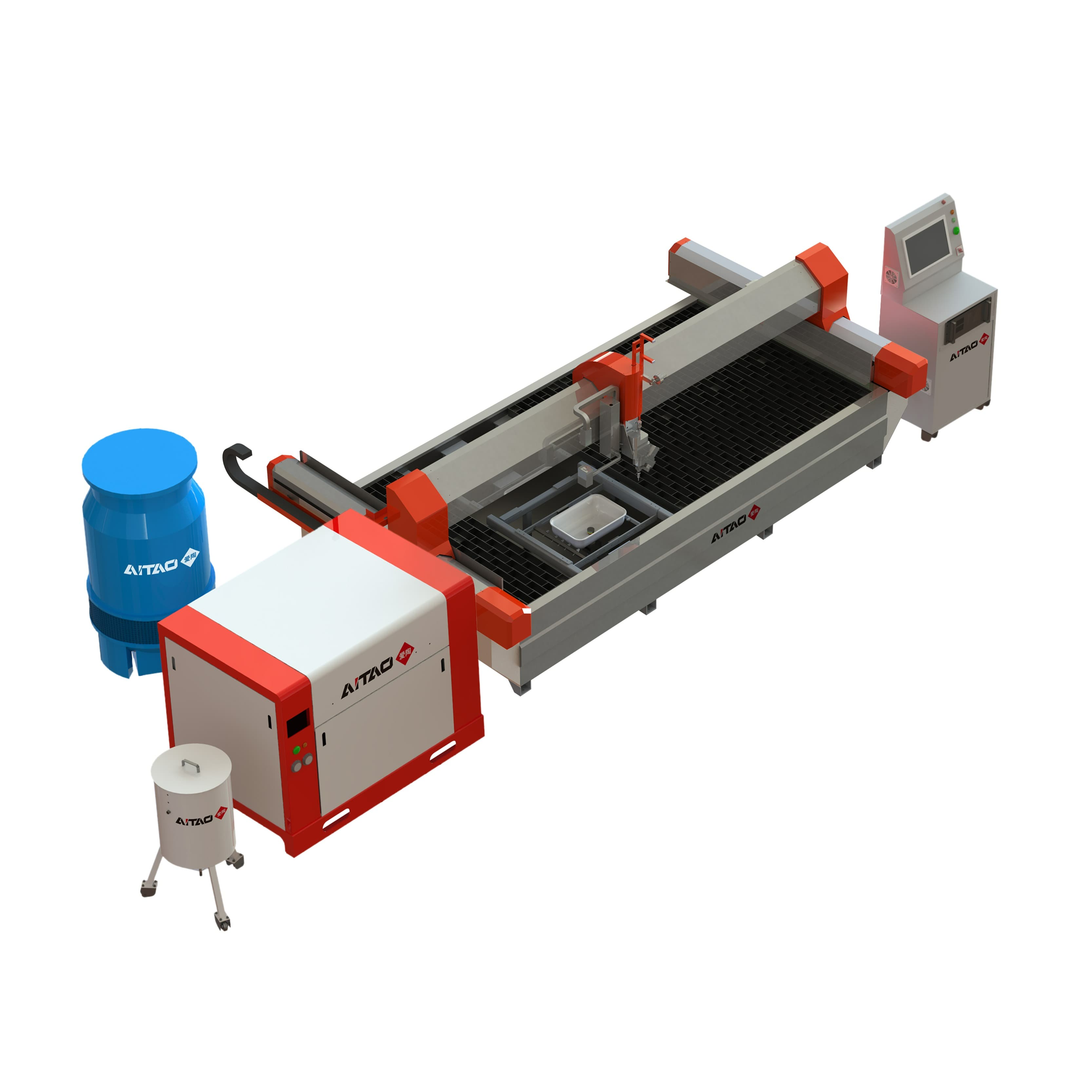

The use of 5-axis waterjet cutting machines has brought about a paradigm change in a variety of sectors by providing exceptional precision, adaptability, and efficiency. As a trusted waterjet cutting machine supplier, AITAO provides various top-quality waterjet cutting machine including 5 axis waterjet cutting machines. Come and shop in AITAO now!