Often hailed as the hardest natural substance on Earth, diamonds are the epitome of strength, beauty, and resilience. It's a common belief that nothing can scratch, let alone cut, a diamond—except another diamond. But does that hold true against the force of high-pressure water? With advancements in technology, the question arises: Can waterjet cutting technology, known for slicing through metal and stone, challenge a diamond's invincibility? This article delves into whether a waterjet can indeed cut through the seemingly impervious diamond.

The Hardness Of Diamonds

Diamonds are composed of carbon atoms arranged in a crystal lattice structure. Each carbon atom makes four strong covalent connections with its neighbors, resulting in a very strong and stable structure. This structure gives diamonds their renowned hardness, making them resistant to scratches and abrasions.

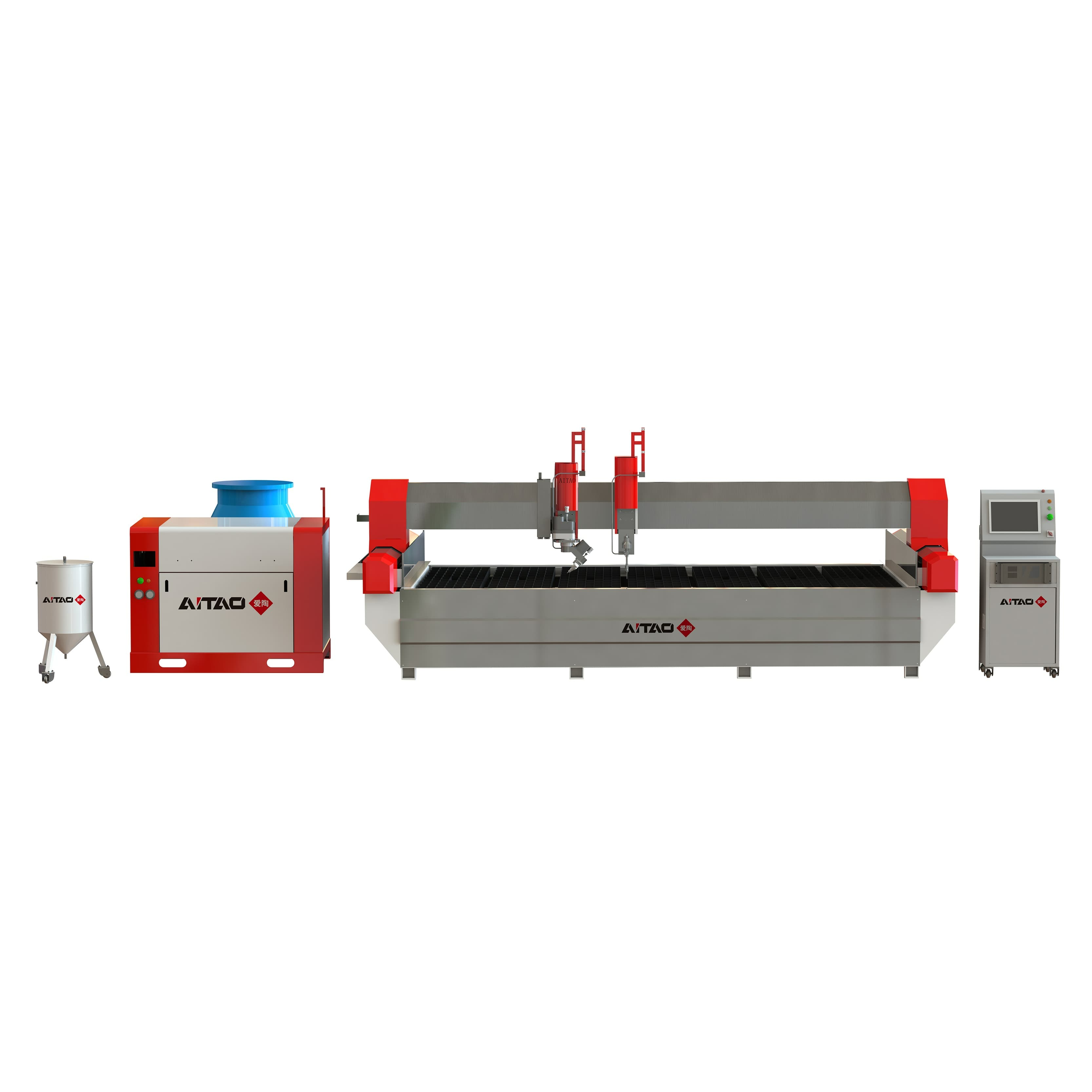

Waterjet Machine For Special Material Processing

Waterjet Cutting Diamond: A Technological Marvel?

The waterjet cutter is a marvel of modern engineering, offering a versatile and precise method for slicing through a myriad of materials. By compressing water to extreme pressures and mixing it with an abrasive substance like garnet, the waterjet propels a concentrated, high-velocity stream through a fine nozzle. This creates a supersonic jet capable of detailed and accurate cutting. But can this technology extend to the realm of cutting diamonds with water, where precision and power must confront unparalleled hardness?

Waterjet Applications In Ceramic Tile Cutting

Can Waterjet Cut Through Diamond?

While waterjets are incredibly powerful, the question of whether they can cut diamonds remains a matter of debate. On the surface, it appears feasible, given that waterjets can cut through materials such as steel, glass, and ceramics. Diamonds, on the other hand, have special qualities that make them difficult to cut.

Diamond Hardness: As previously mentioned, diamonds are renowned for their exceptional hardness, ranking as a 10 on the Mohs scale of mineral hardness. Diamonds are not readily scratched or abraded at this degree of hardness, and their strong covalent bonds make them resistant to typical cutting processes.

Abrasive Properties: Waterjets typically use abrasive particles like garnet or aluminum oxide to aid in cutting. While these abrasives are good for cutting metals and glass, they may not be adequate for cutting diamonds. Diamonds, being harder than most abrasives, could resist erosion from the abrasive material.

Risk Of Fractures: Diamonds are also brittle, which means they are susceptible to cracking or shattering under stress. A waterjet cutting machine's intense jet of water and abrasive particles can cause vibrations and pressure points on the diamond's surface, potentially leading to fractures.

Special Material Processing With Waterjet Cutting

Heat Generation: The friction generated during the cutting process can create heat. While waterjets are noted for their ability to cut without releasing much heat, the high-pressure abrasive stream can nevertheless create enough heat to jeopardize the diamond's integrity, especially when cutting complicated shapes or facets.

Precision And Control: Achieving the level of precision required for diamond cutting, particularly in the jewelry industry, is a formidable challenge with waterjets. When creating elaborate gemstone patterns, traditional procedures such as diamond-on-diamond cutting or laser cutting provide better control and accuracy.

While cutting diamonds using waterjets is theoretically conceivable, it is not a practical or frequent process. The extreme hardness, brittleness, and heat sensitivity of diamonds make them unsuitable candidates for waterjet cutting, at least for delicate tasks such as shaping gemstones for jewelry. Traditional diamond-cutting processes are favored owing to their accuracy and ability to minimize waste.

Conclusion

The exploration of cutting-edge tools like waterjets opens up a world of possibilities in the domain of modern technology. Yet, when it comes to the precise art of diamond cutting, it appears that the tried-and-true techniques—diamond-on-diamond cutting and laser cutting—still reign supreme. These methods have stood the test of time for their precision and efficiency. Nevertheless, the conversation about water's potential to cut through diamond continues, reflecting the ever-evolving landscape of industrial capabilities. However, when it comes to cutting diamonds, the traditional methods, including diamond-on-diamond cutting or laser cutting, continue to be the go-to choices.

However, if you are looking for an ideal machine for cutting, such as textiles, rubber, composites, stone, tile, glass, etc, AITAO can help you. Contact us for more details now!

FAQs

1. Can High-Pressure Water Cut Diamond?

While high-pressure waterjets are powerful enough to cut through steel and stone, cutting a diamond is a different story. Diamonds are the hardest known natural material, making them resistant to being cut by water alone, even at high pressures. Waterjets used for cutting diamonds would need to incorporate other methods or materials to assist in the cutting process.

2. Can a waterjet cut through the hardest materials like diamonds?

Waterjets are highly effective for cutting a wide range of materials, including metals, stone, and glass. However, when it comes to diamonds, their extreme hardness poses a significant challenge. Traditional diamond cutting techniques, such as laser cutting or using another diamond, are still necessary to shape and facet these precious stones accurately.

3. How do they cut diamonds if not with waterjet technology?

Diamonds are typically cut using specialized tools and techniques that take advantage of the crystal structure of the diamond itself. These methods include laser cutting, sawing with diamond-impregnated blades, or cleaving along the diamond's natural planes. These techniques allow for the precision and care needed to cut and polish diamonds without causing damage.