Chamfering, a crucial process in manufacturing and metalworking, involves cutting or grinding away the sharp edges of a workpiece to create a beveled edge, also known as a chamfer. This not only improves the product's aesthetics but also its usefulness by removing sharp edges that might cause harm or damage. Choosing the right chamfering machine is essential for achieving precise and efficient results. In this guide, we'll delve into the factors to consider when selecting a chamfering machine to meet your specific needs.

Determine Your Chamfering Requirements

Before delving into the specifics of chamfering machines, it's crucial to have a clear understanding of your chamfering requirements. Consider the kind and thickness of the materials you'll be dealing with, the size and angle of chamfers required, and the anticipated production volume. For example, if you're working with thin metal sheets, you may require a machine capable of precision chamfering at various angles, whereas if you're chamfering large volumes of wooden beams, you may prioritize speed and efficiency over precision.

Understand the Types of Chamfering Machines

Each form of chamfering machine has advantages and disadvantages, so it's critical to choose which type is appropriate for your unique requirements. Manual chamfering machines are suitable for small-scale operations or occasional chamfering tasks, offering simplicity and affordability. Automatic chamfering machines are ideal for high-volume production environments where efficiency and consistency are paramount. Portable chamfering machines are adaptable to on-site or field operations, providing flexibility and simplicity of movement.

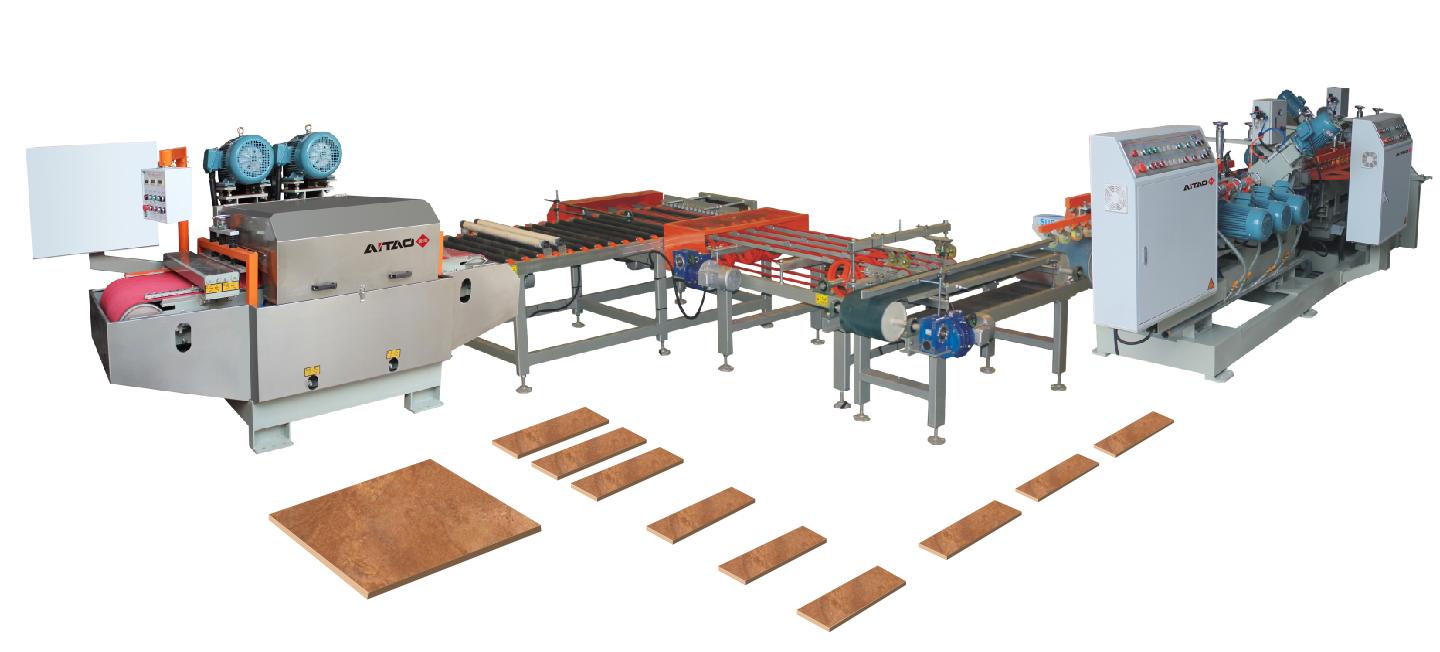

Professional Porcelain Chamfering Equipment

Consider Material Compatibility

Different chamfering machines are designed to work with specific materials, so it's crucial to ensure compatibility with the materials you'll be chamfering. For example, some machines are designed for metal or plastic, whilst others may be better suited to wood or composite materials. Using the wrong machine for the material can lead to subpar results, increased wear and tear on the machine, and potential damage to the workpiece.

Evaluate Chamfering Capabilities

The chamfering capabilities of a machine determine its versatility and suitability for various applications. Consider the range of chamfer sizes and angles that the machine can achieve, as well as any adjustable settings that allow for customization. Machines with a wide range of chamfering capabilities are more flexible and can meet a variety of project needs, making them an invaluable asset in dynamic production environments.

Review Precision and Accuracy

Precision and precision are essential in chamfering, especially for applications requiring tight tolerances or elaborate patterns. Look for chamfering machines with modern features like digital controls, precision guides, and changeable depth settings to ensure consistent and exact chamfering. Machines that offer micro-adjustments and fine-tuning capabilities enable operators to achieve the desired chamfer dimensions with utmost accuracy, minimizing rework and scrap.

Porcelain Tile Chamfering Machine Suppliers

Assess Ease of Operation and Maintenance

The ease of operation and maintenance significantly impacts productivity and uptime in a manufacturing or metalworking environment. Choose a chamfering machine with simple controls, ergonomic design, and user-friendly interfaces to simplify operation and shorten operator training time. Additionally, consider maintenance requirements such as tool replacement, lubrication, and cleaning procedures. Machines with accessible components and straightforward maintenance protocols facilitate routine upkeep and prolong the lifespan of the equipment.

Explore Safety Features

When choosing a chamfering machine, safety should always come first to safeguard operators from potential risks and reduce workplace accidents. Look for machines with advanced safety features including emergency stop buttons, protective guards, and automated shut-off systems. Consider ergonomic design components to reduce operator fatigue and encourage safe working habits. Investing in a machine with solid safety measures not only assures compliance with industry laws but also promotes a safety culture in the workplace.

Automatic Porcelain Chamfering Machine For Sale

Consider Budget and Return on Investment

While performance and quality should be prioritized, economic concerns are equally important when purchasing a chamfering machine. Evaluate the initial investment cost of the machine in relation to its long-term benefits and return on investment. Consider productivity improvements, reduced scrap and rework, maintenance costs, and the possibility for future expansion or upgrades. Choosing a machine that offers the best balance of features, performance, and affordability ensures optimal value for your investment and contributes to the overall profitability of your operation.

Conclusion

Choosing the right chamfering machine is essential for achieving precise, efficient, and safe chamfering operations. If you are looking for a high-quality chamfering machine on the market, AITAO can help you. As a professional industrial cutting equipment supplier, we specialize in offering various industrial cutting equipment including chamfering machines to fit different applications. Upgrade your business with our top-quality products now!