Discover how 4-axis milling CNC is revolutionizing manufacturing processes. Computer Numerical Control (CNC) machines, particularly the 4-axis CNC variant, have transformed the manufacturing landscape by automating tasks and significantly improving precision. Unlike traditional CNC machines, a 4-axis CNC machine operates on four different axes, offering unparalleled diversity and complexity in machining operations. This article serves as your comprehensive guide to understanding the capabilities and advantages of 4-axis CNC machines, ensuring you're well-informed about this innovative technology.

What Is A 4-axis CNC Machine?

What exactly is a 4-axis CNC machine? It's an advanced manufacturing tool that elevates the precision of cutting, carving, and shaping a wide array of materials, including metals, plastics, and composites. The defining feature of a 4-axis CNC machine is its additional rotating axis, known as the A-axis, which complements the traditional X, Y, and Z axes of its 3-axis counterparts. This added axis introduces the ability to perform complex machining tasks that were previously unattainable, marking a significant leap in manufacturing technology.

Understanding The Axes

X, Y, and Z Axes: The fundamental axes of a CNC machine are the X, Y, and Z axes, representing horizontal and vertical movements. The X-axis normally goes from left to right, the Y-axis from front to back, and the Z-axis controls the tool's depth vertically. These three axes define the spatial placement of the tool and workpiece as a whole.

A-Axis: The A-axis is the distinguishing feature of a 4-axis CNC machine, introducing rotation to the machining process. This rotational capability allows the workpiece to be tilted or rotated, providing an additional degree of freedom. The A-axis increases the machine's capabilities by allowing it to approach the workpiece from different angles, resulting in greater flexibility and complexity in machining jobs.

Adavantages Of 4-Axis CNC Machines

Exploring the Advantages of 4-Axis CNC Machines:

Complex Contouring

One of the standout benefits of 4-axis CNC machines is their unparalleled ability in complex contouring. These machines excel in executing precise contouring and sculpting tasks, a feat made possible by the rotational function of the A-axis. This capability enables the creation of intricate and detailed components that are beyond the reach of conventional 3-axis machines, showcasing the revolutionary impact of 4-axis milling CNC in manufacturing.

Enhanced Precision

The addition of the A-axis significantly enhances precision in machining. With the ability to tilt or rotate the workpiece, manufacturers can achieve more accurate cuts and angles, resulting in a higher level of precision in the final product. This is especially beneficial in areas where accuracy is essential, such as aerospace and medical production.

High-Speed Ceramic Tile Cutting Tools

Reduced Setup Time

4-axis CNC machines simplify the production process by removing the requirement for frequent workpiece repositioning. The rotational capability of the A-axis enables machining from different angles without manual intervention, reducing setup time and increasing overall production efficiency.

Multi-Sided Machining

A notable application of 4-axis CNC machines is their capability to machine multiple sides of a workpiece without requiring manual repositioning. This is especially beneficial for making complicated components that need machining on several surfaces, resulting in a more streamlined and efficient manufacturing process.

Cylindrical Machining

The A-axis allows 4-axis CNC machines to excel in cylindrical machining tasks. This feature is useful for applications such as engraving on curved or cylindrical items, broadening the range of goods that may be produced economically using this technology.

Challenges And Considerations

Although the 4-axis CNC machine has various advantages, it also has some challenges and considerations as the following:

Programming Complexity

Operating a 4-axis CNC machine demands more advanced programming skills compared to a 3-axis machine. The addition of the rotating axis increases programming complexity, requiring operators to have a complete awareness of the machine's capabilities and subtleties.

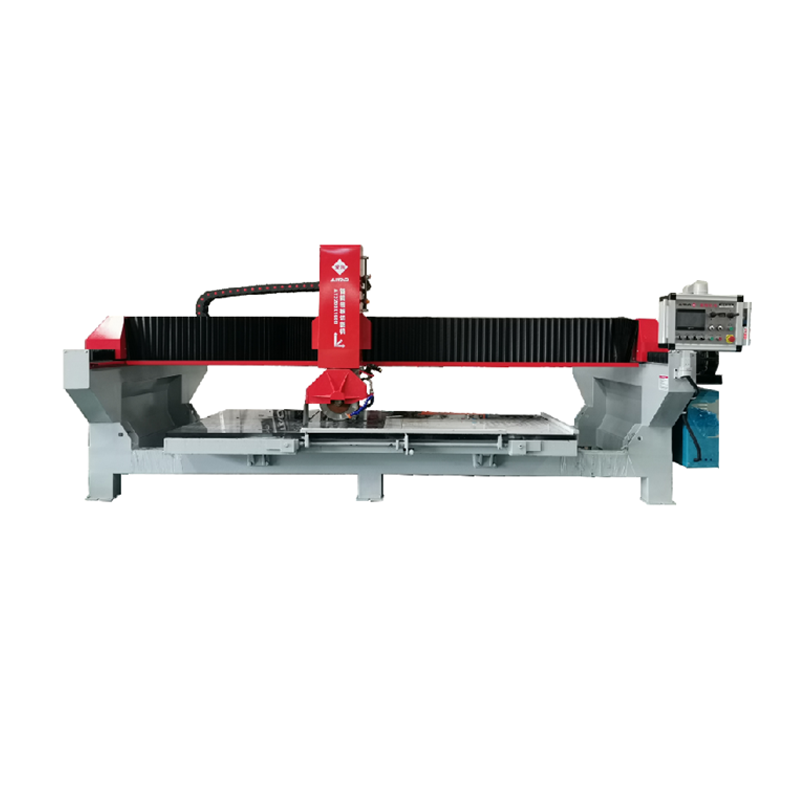

Industrial CNC Bridge Saw Suppliers

Tool Interference

When using the A-axis, careful preparation is required to avoid tool interference. Improper programming may lead to collisions between the tool and the workpiece, potentially causing damage to both the machine and the part being machined. Operators must be vigilant in ensuring collision-free toolpaths.

Cost

While 4-axis CNC machines offer advanced capabilities, they tend to be more expensive than their 3-axis counterparts. To analyze the viability and return on investment, the initial investment and operational expenditures should be carefully addressed, especially for smaller enterprises or those with limited budgets.

Conclusion

In conclusion, the 4-axis CNC machine represents a monumental advancement in manufacturing technology, introducing a new dimension of complexity and precision to the production process. Despite the challenges associated with programming complexity and cost, the unparalleled diversity, precision, and efficiency it offers make it an indispensable tool in the modern industrial landscape. As a premier CNC machine supplier, AITAO is committed to delivering the highest quality products. For those seeking to leverage the revolutionary capabilities of 4-axis milling CNC, we invite you to explore our extensive range of high-tech CNC machines. Contact us today for more details and elevate your manufacturing processes to new heights.

FAQs

1. How does a 4-axis CNC machine differ from a 3-axis machine?

Answer: A 4-axis CNC machine adds a rotational axis (A-axis) to the X, Y, and Z axes found in a 3-axis machine. This rotational capability allows for greater flexibility in approaching the workpiece from various angles, enabling more complex machining operations.

2. What types of materials can be machined using a 4-axis CNC machine?

Answer: 4-axis CNC machines are versatile and can be used to machine a wide range of materials, including metals (aluminum, steel), plastics, composites, and wood. The rotational axis enhances their ability to handle diverse materials and complex geometries.

3. What are the common applications of 4-axis CNC machines?

Answer: 4-axis CNC machines are widely used for complex contouring, sculpting, and engraving tasks. They excel in applications requiring multi-sided machining, enhanced precision, and the ability to work on cylindrical surfaces. Industries such as aerospace, automotive, and medical manufacturing benefit from their advanced capabilities.

4. Are 4-axis CNC machines suitable for small-scale businesses?

Answer: The suitability of a 4-axis CNC machine for small-scale businesses depends on the specific needs and budget constraints. While these machines offer advanced capabilities, the initial investment and operational costs should be carefully considered. Smaller businesses may explore the feasibility based on their production requirements.

5. How do 4-axis CNC machines contribute to reducing setup time?

Answer: The rotational capability of the A-axis eliminates the need for frequent repositioning of the workpiece during machining. This reduces setup time significantly as the machine can approach the workpiece from different angles without manual intervention, increasing overall production efficiency.

6. Can 4-axis CNC machines handle large-scale production?

Answer: Yes, 4-axis CNC machines are capable of handling large-scale production, provided they are appropriately sized and equipped. Their ability to efficiently machine complex parts and reduce setup time makes them suitable for a range of production volumes, from prototypes to high-volume manufacturing.