Water jet cutting machines have transformed the precision cutting industry by providing a diverse and effective means to slice through various materials. From metals to composites, these machines create precise cuts by utilizing the force of water and abrasive materials In this article, we'll dive into the world of water jet cutting.

What Is Water Jet Cutting?

Water jet cutting is a revolutionary method that uses the power of high-pressure water streams to cut through various materials with precision. What sets this process apart is its ability to maintain the structural integrity of the material being cut, as it generates minimal heat during the cutting process.

At the core of water jet cutting machines are high-pressure pumps that generate the immense pressure needed to create the cutting stream. These pumps are typically powered by electric motors or hydraulic systems. The pressurized water is then channeled through a tiny nozzle, narrowing and increasing the velocity of the stream. The combination of pressure and velocity creates a forceful water stream capable of eroding and cutting through materials.

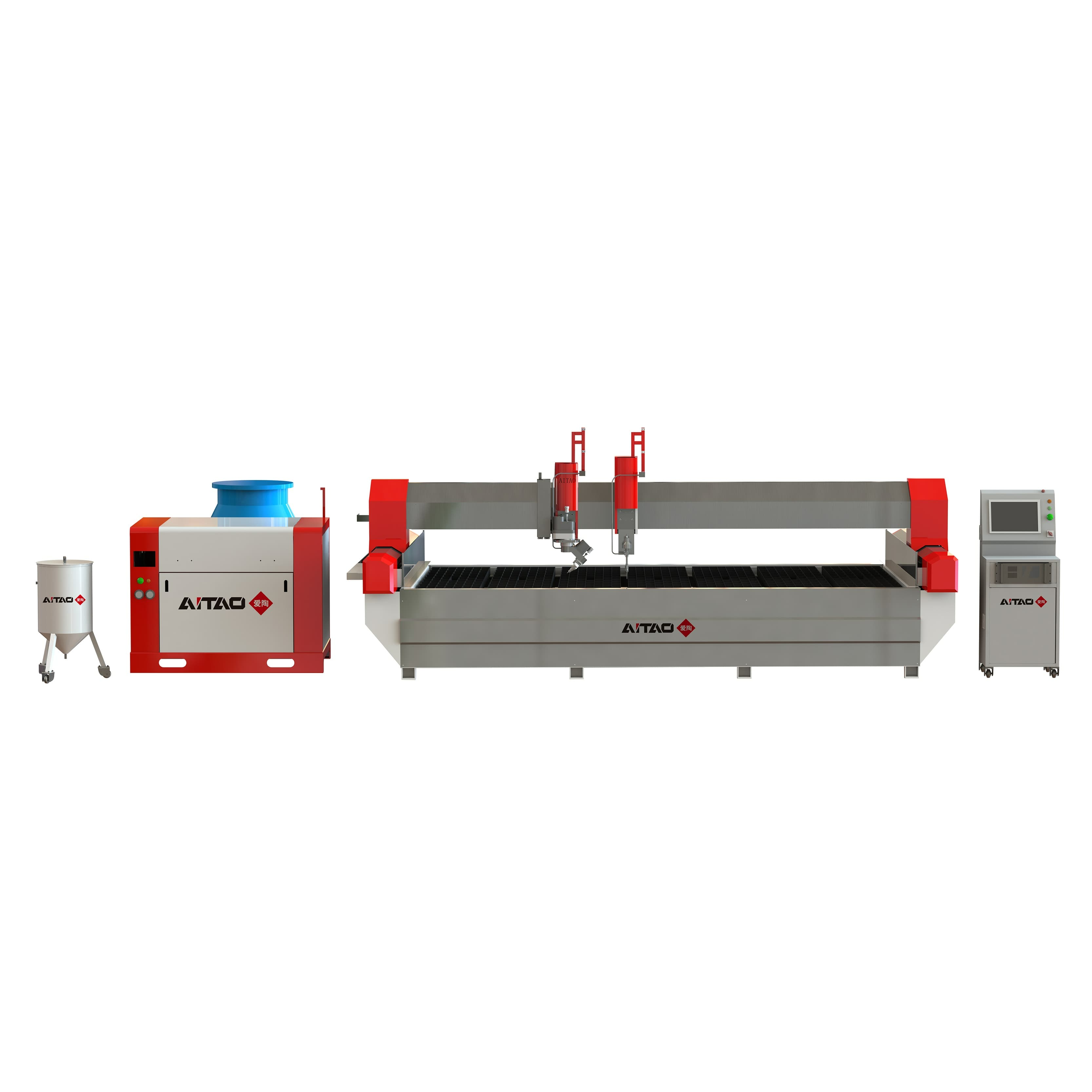

Composite Material Waterjet Cutting Machine

How Does A Water Jet Cutting Machine Work?

Water jet cutting can be categorized into two main types including abrasive water jet cutting and pure water jet cutting.

In abrasive water jet cutting, the water stream is mixed with abrasive particles before being expelled from the nozzle. This mixture of water and abrasives creates a highly concentrated cutting force capable of slicing through materials like steel, titanium, and ceramics. The abrasive particles essentially assist in the erosion process by increasing the cutting power.

On the other hand, pure water jet cutting is employed for softer materials that don't require abrasive assistance. This technique is great for cutting materials such as rubber, foam, paper, and some plastics. The pure water jet cuts the material cleanly and precisely without creating heat-induced distortions.

The Process of A Water Jet Cutting

The process of water jet cutting involves several key steps:

Pressurization - The water is pressurized by the high-pressure pump, reaching levels that give it immense cutting power.

Nozzle Assembly - A tiny nozzle directs the pressured water. The size and form of the nozzle are critical in shaping the cutting stream.

Abrasive Introduction - If abrasive water jet cutting is employed, abrasive particles are introduced into the pressurized water stream.

Material Erosion - The high-speed water or abrasive mixture exits the nozzle and comes into contact with the material to be cut. Because of the strong pressure and cutting action, the erosion generates a perfect cut along the intended line.

Ceramic Material Processing Waterjet Machine

Types Of Water Jet Cutting Machines

Water jet cutting technology has evolved to accommodate various industrial and creative needs. As a result, different types of water jet cutting machines have emerged, each tailored to specific applications and requirements. Let's explore some of the prominent types:

Water Jet Cutting Robots

Water jet cutting robots combine water jet cutting accuracy with robotic automation versatility. These machines are perfect for businesses that demand repeated, precise cutting activities. The robotic arm is outfitted with a water jet cutting nozzle that allows it to travel along pre-programmed lines to make complex cuts on materials. This equipment is often employed in sectors such as automobile production, where constant and exact cuts are required for part creation.

CNC Water Jet Cutting Machines

Computer Numerical Control (CNC) water jet cutting machines bring digital precision to the cutting process. These machines are guided by digital designs, allowing operators to input specific cutting patterns and dimensions. The CNC system translates these instructions into precise movements of the water jet nozzle. This machine is popular because of its capacity to make elaborate and complicated cuts with minimum human assistance. CNC water jet cutting machines are frequently used in industries that demand specific customisation, such as architecture and art.

Micro Water Jet Cutting Machines

Micro water jet cutting machines specialize in precision cutting on a small scale. These machines are capable of creating intricate cuts in materials as delicate as thin films and medical devices. Micro water jet cutting is critical in sectors that need microscopic precision, such as the manufacture of electronics and medical equipment. The capacity of the technology to generate clean and precise cuts without heat-induced distortion is extremely useful in these applications.

Portable Water Jet Cutting Machines

Portable water jet cutting machines offer the convenience of mobility without compromising on cutting capabilities. These machines are designed to be compact and easy to transport, making them suitable for on-site cutting tasks or applications where space is limited. Despite their compact size, portable water jet cutting machines can easily cut through a range of materials. They are frequently utilized in areas such as building and maintenance.

Conclusion

In the world of modern manufacturing and design, water jet cutting machines have carved a niche with their ability to provide accurate, versatile, and efficient cutting solutions across diverse industries. If you are looking for trusted industrial tile cutter suppliers, look no further than AITAO! We offer a wide range of water jet cutting machines, contact us for more product details now!