Ever marveled at how a stream of water can shape the world of manufacturing? CNC water jet cutting is that wonder, a technique so versatile that it's like the Swiss Army knife of the cutting world. From the softest textiles to the toughest composites, this tech slices through with a precision that's as cool as the water it uses—literally.

Versatility Across Materials: The CNC Water Jet Cutting Edge

With the CNC water jet cutting technology, designers and manufacturers across various industries enjoy a level of versatility and precision that was once unimaginable. This method is not limited to just metals and stones; it extends to softer materials such as textiles, offering a non-thermal cutting process that keeps the fibers intact and edges clean. Whether it's the delicate art of fashion design, requiring intricate cuts on silk or the robust needs of industrial denim processing, water jet cutting ensures a fine finish without fraying, a common issue with traditional cutting methods. Such precision not only elevates the quality of the final product but also significantly reduces material waste, aligning with sustainable manufacturing practices.

Rubber

Precision is everything in the rubber sector. Gaskets, seals, and other rubber components must be precisely fitted. In this area, CNC water jet cutting excels, offering very precise cuts without heat-induced damage or deformation in the rubber material. The cold cutting process ensures that the rubber remains in its original state, offering a reliable solution for industries where tight tolerances are crucial, such as automotive and manufacturing.

Waterjet Cutting For Large Scale Ceramic Tile Packaging

Composites

Composites are the strong, silent types—tough as nails but not the easiest to get along with when it comes to cutting. CNC water jet cutting gets them, though. It cuts to the chase without a single fiber out of place, which is why the aerospace and automotive folks wouldn't trade it for the world.

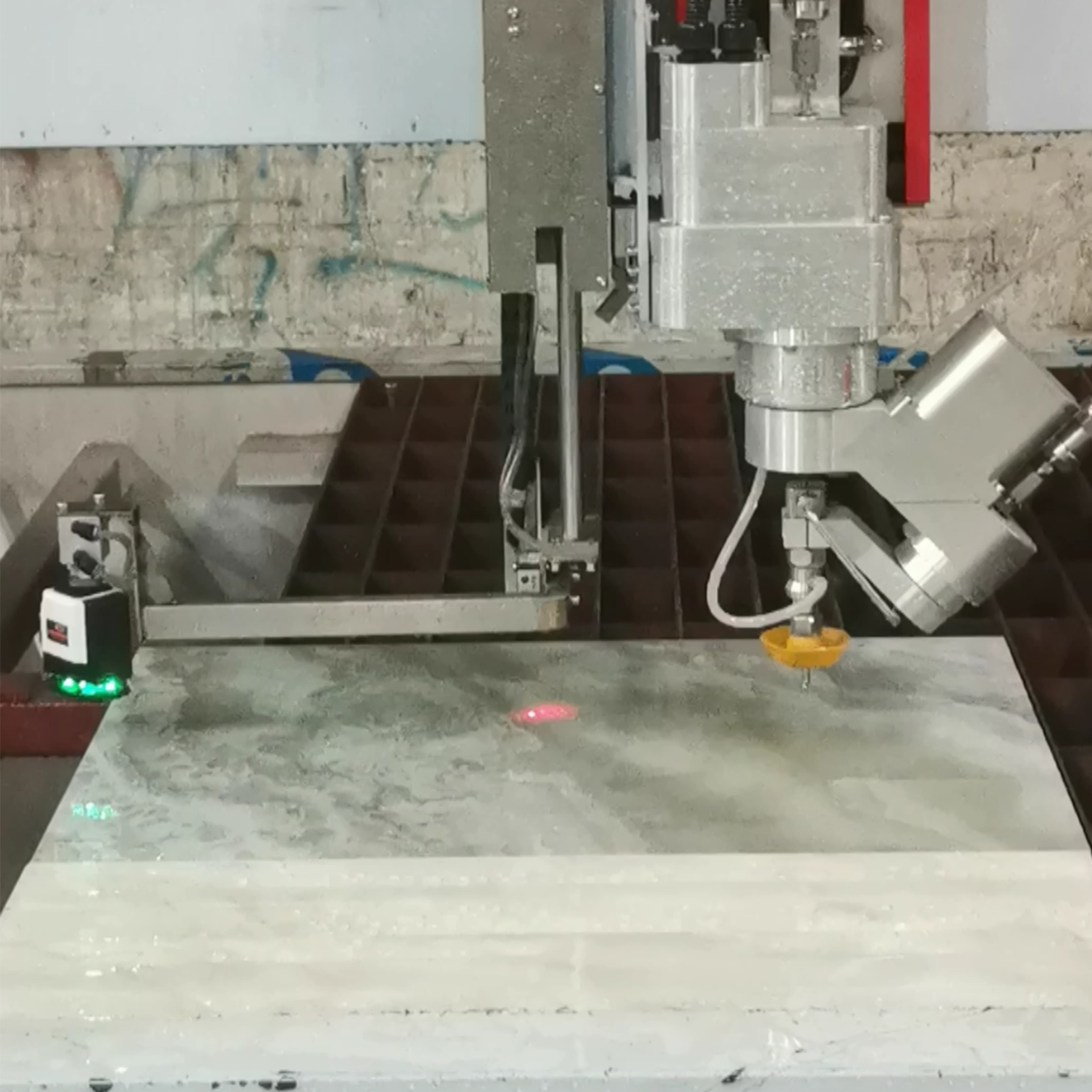

Stone

Ever seen a countertop that took your breath away or a tile mosaic that told a story? That's CNC water jet cutting, working its magic on stone and tile. It's like a sculptor with the finesse of a jeweler, turning slabs of marble and squares of ceramic into works of art that fit together just so.

Waterjet Cutting For Ceramic Tile Packaging Line

Tile

For the tile industry, CNC water jet cutting is a transformative asset. Not only does this technology excel in shaping standard ceramic and porcelain tiles, but it also thrives in the precision crafting of specialized water jet tile cutting machines. These machines are adept at creating elaborate and bespoke tile patterns, allowing for the production of everything from ornate mosaics to sophisticated floor designs. The precision of water jet cutting ensures that each piece fits seamlessly, enhancing the aesthetic appeal and facilitating a smoother installation process. Water jet cutting guarantees clean edges and excellent fits, improving the visual attractiveness of tile installations while shortening installation time.

Glass

CNC water jet cutting has revolutionized how glass is cut and molded. It is employed in the creation of elaborate glass designs, beautiful glass art, and architectural glass components. This technology eliminates the risk of chipping or cracking in glass, resulting in polished edges and a flawless finish. It is especially useful in professions where accuracy and aesthetics are important, such as painting and architecture.

Acrylic

Acrylic, a popular material for signs, displays, and ornamental products, benefits from the accuracy of CNC water jet cutting. The process provides clean, polished edges, giving acrylic items a professional appearance. This makes it an ideal choice for producing intricate signage, eye-catching displays, and elegant decorative pieces. Additionally, the cold cutting process minimizes the risk of heat-induced distortions, maintaining the material's clarity and transparency.

Ceramic Material Processing Waterjet Machine

Wood

CNC water jet cutting in the woodworking industry offers precision and versatility, making it suitable for a variety of wood types. From crafting wooden puzzles to creating intricate cabinetry, water jet cutting facilitates detailed designs and clean cuts. The cold cutting procedure preserves the inherent features of the wood, such as grain and color, while eliminating material waste.

Paper and Cardboard

CNC water jet cutting enables highly personalized and complicated products in the paper and cardboard industries. Water jet cutting produces clean, accurate edges and exquisite details for complex wedding invitations and distinctive package designs. This technology revolutionizes the production of custom designs, reducing the need for additional finishing steps and enhancing the overall quality of paper and cardboard products.

Conclusion

CNC water jet cutting isn't just a tool; it's a revolution that's changing the game across industries. With AITAO's lineup of machines, tailored to the diverse materials we've toured, the only limit is your imagination. Whether it's fashion or construction, aerospace or artistry, these machines are ready to turn your vision into reality.

Q1: What types of materials can CNC water jet cutting machines handle?

A1:CNC water jet cutting machines are incredibly versatile, capable of handling a wide array of materials. They can precisely cut through textiles, rubber, various composites like carbon fiber and Kevlar, natural and engineered stones, tiles, glass, acrylic, woods of all types, as well as paper and cardboard. This makes them suitable for applications in industries ranging from fashion and automotive to aerospace and construction.

Q2: Can water jet cutting be used for intricate tile designs, and how does it compare to traditional tile cutting methods?

A2:Yes, water jet cutting is exceptionally well-suited for creating intricate tile designs. Unlike traditional tile cutting methods, which may be limited in precision and can cause chipping or cracking, water jet cutting can produce complex shapes and delicate patterns with smooth, clean edges. This technology is ideal for custom tile work, including decorative mosaics and detailed inlays that require a high degree of accuracy.

Q3: Are there any limitations to the types of patterns and designs that can be achieved with CNC water jet cutting?

A3:CNC water jet cutting offers unparalleled flexibility in the types of patterns and designs it can create. The only limitations are related to the size of the cutting table and the material being cut. Otherwise, if a design can be drawn, it can typically be cut by a CNC water jet. This allows for the production of highly customized pieces and intricate designs that are difficult or impossible to achieve with other cutting methods.