Categorys

Hot Product

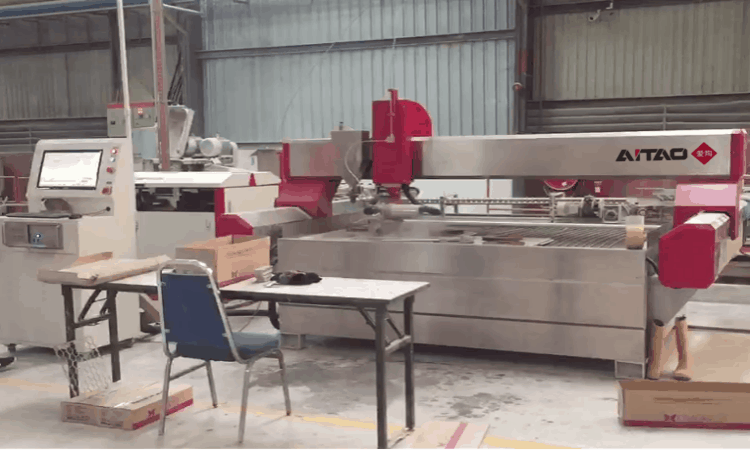

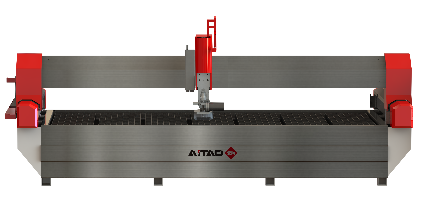

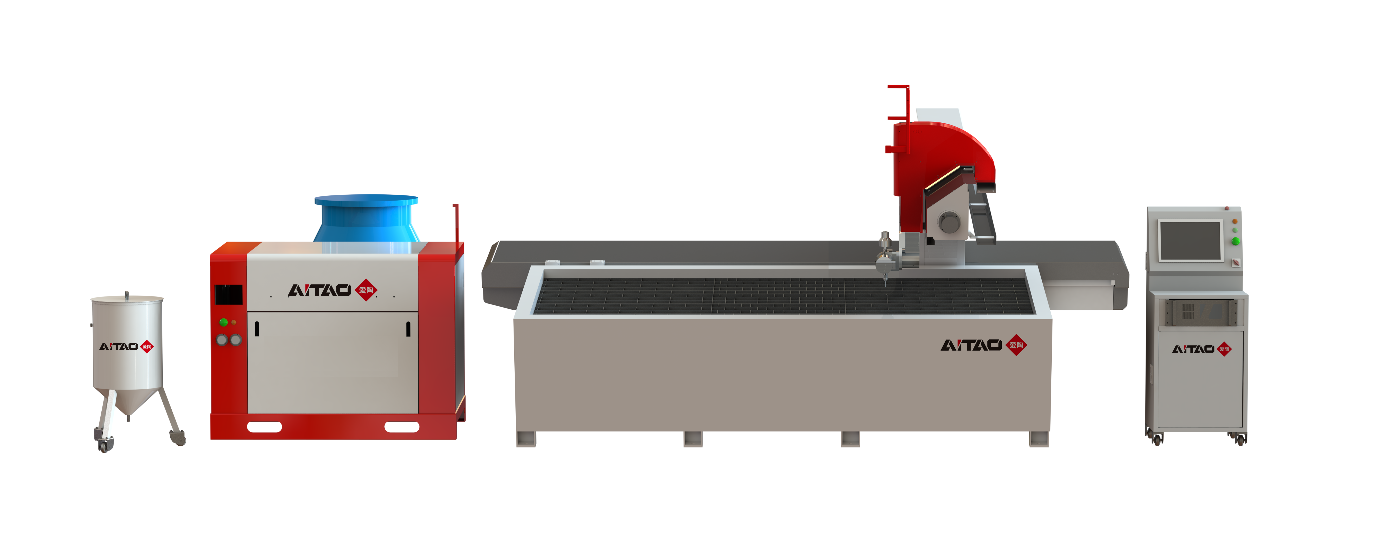

AB 5 axis CNC Water Jet Cutting Machine

5-axis CNC water jet cutting machine, cutting speed will be faster and more efficient. Automatically remove the bevel or cut groove, no secondary processing, saving manpower and material resources, greatly reducing processing costs and environmental pollution.

This machine has automatic CNC control system for required angle, high precision, no clearance, maintenance-free, can cut different materials such as: ceramics, metal, stone, glass and composite materials.

AB 5 Axis Waterjet Cutting Machine is the best solution for making stone pattern, stone design.

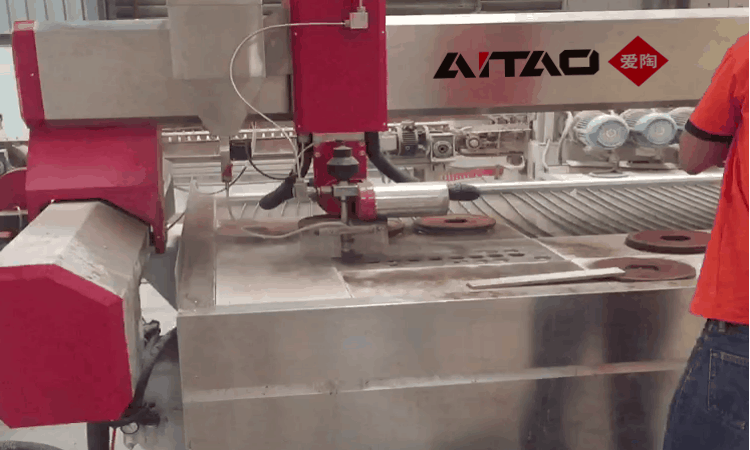

ADVANTAGES OF AB 5 AXIS CUTTING HEAD:

1. Adopt AB axis design, realize 5 axis (X. Y. Z. A.B) move.

2. Structure more tight for the Waterproof and dust proof. electrical wiring has a tidier and clear layout.

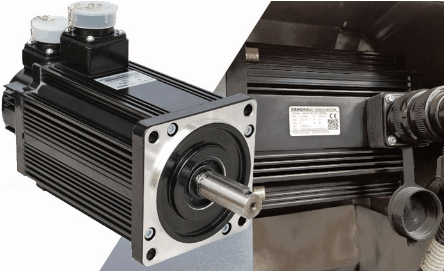

3. Adopt international high-end brand servo motor and servo driver to make the control accuracy higher.Reasonable design, evenly the force, effectively improve the water jet operating life and reliability.

Main Features

1. The blade is tilted in any direction to cut, eliminating the phenomenon of uneven cutting surface (eliminating the phenomenon of small surface and large bottom).

2. Adopting an AB axis structure design, achieving CNC five axis (X, Y, Z, A, B) linkage;

3. Adopting high-quality servo motors and servo drivers for higher control accuracy;

4. Reasonable design, balanced stress, effectively improving the operating life and reliability of the five axis water jet;

5. Adopting an integrated dustproof sealing structure, the screw guide rail adopts a stainless steel fully enclosed oil bubble structure, reducing maintenance costs, being durable, and improving the service life of the equipment;

6. Realizing the cutting blade to cut at any angle within a range of ± 5 degrees has excellent performance in the processing of materials such as marble and ceramic tiles.

7. Cutting with angle solves the problem that the lower part of the cutting surface is uneven and affects the assembly quality. In the stone mosaic process, it can be directly assembled with glue without polishing, reducing production links and Labor burden;

8. Can process relatively complex products, such as arc plate cutting and cylindrical plate stitching;

9. There is no need to pause when turning, and there are no turning circles, making the cutting speed faster. The uneven cutting surface will not affect the collage.

10. Make complex graphics more detailed and beautiful, and simplify the operation of complex graphics.

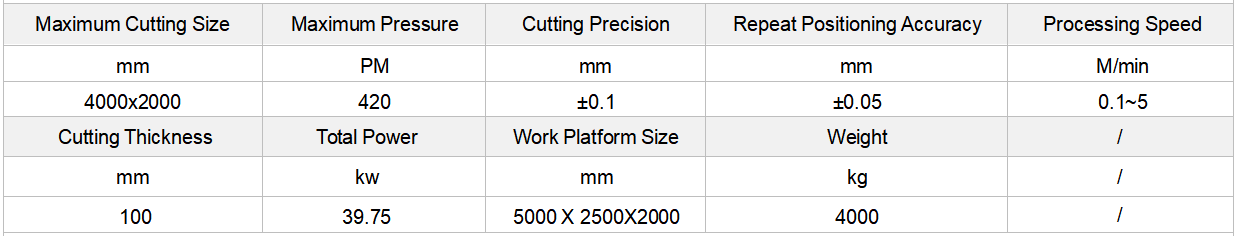

Equipment parameters

Application

* Stone/Ceramic industries such as used for countertops, art puzzles, flooring Inlays and mosaics.

* Glass industry , such as bathroom glass, shop window glass, automotive glass and appliance glass.

* Metal industries such as Decoration, decoration in the stainless steel and other metal cutting process, equipment cover cutting, Cutting of metal parts.

* Gasket Cutting

* Foam Product Cutting.

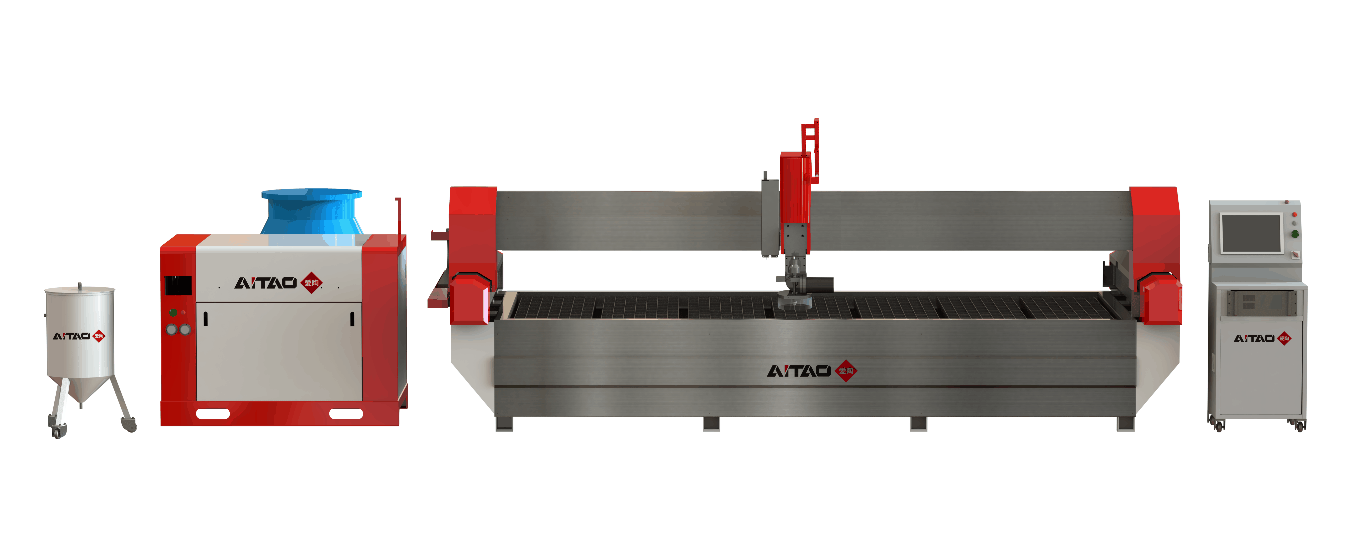

Main Equipment Description

cutting platform specifications

AT3020:3000x2000(mm)

AT4020 : 4000x2000(mm)

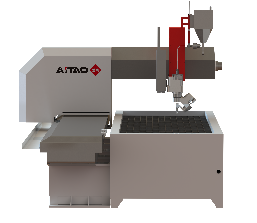

Cantilever cutting platform specifications:

AT2515:2600 x 1600(mm) AT3015:3100 x 1600(mm)

Cutting accuracy: ± 0.1mm

Repetitive accuracy: ± 0.05

Moving parts: Taiwan "ABBA" or "TBI"

Linear guide rail/ball screw "oil bubble type

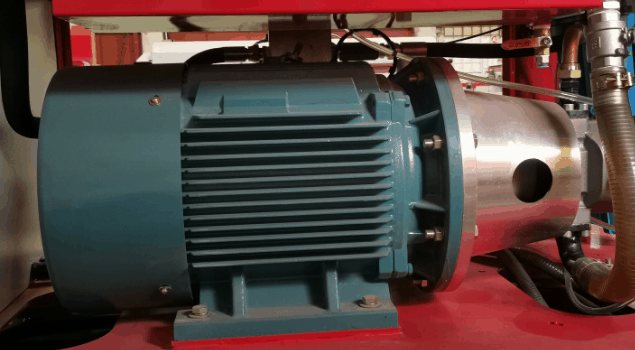

X-axis running speed: 0-5000mm/min; 1.5KW

Y-axis running speed: 0-5000mm/min; 1.5KW

Z-axis running speed: 0-1000mm/min; 0.40KW

A-axis rotation angle: ± 70 degrees; 0.20KW

C-axis rotation angle: infinite; 0.20KW

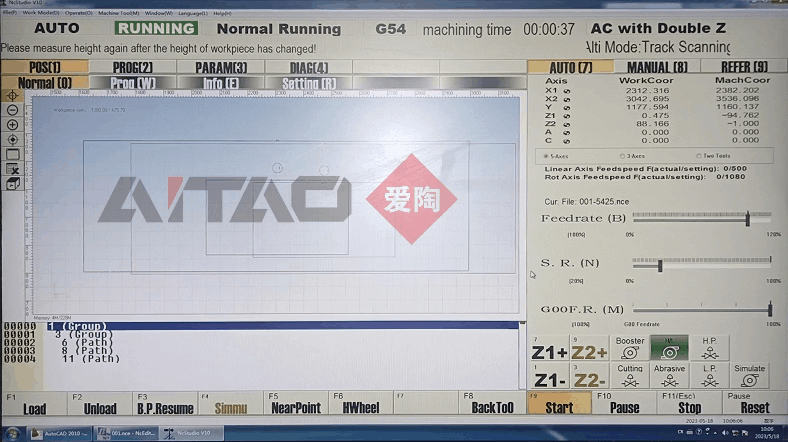

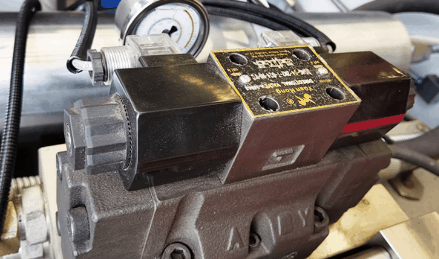

Control system:CNC driver;

Industrial control computer; JAWJ cutting software (NC Studio V-9.38)

Based on Win7 32-bit, genuine Shanghai Naikai Ncstudio

Operation interface: Chinese/English can be switched freely

Z-axis stroke: 110mm

Centralized lubrication system makes machine tool operation more reliable

Servo motor: Weizhi AC servo

Power supply: 220V/380V/50HZ

|

model |

AT420 |

AT420Ⅱ |

AT450 |

|

Max.pressure :(Mpa) |

420 |

420 |

380 |

|

Long time working pressure:(Mpa) |

280-380 |

280-380 |

280-380 |

|

Intensifier ratio :(L/min) |

1:20 |

1:20 |

1:20 |

|

Max.flow rate :(L) |

3.7 |

4.6 |

6.8 |

|

Inlet pressure :(Mpa) |

0.4 |

0.6 |

0.6 |

|

Max.rifice size :(mm) |

0.33 |

0.35 |

0.35 |

|

Max.pump flow :(L/min) |

105 |

148 |

148 |

|

Max.pump pressure : (Mpa) |

31.5 |

31.5 |

31.5 |

|

Max.pump pressure : (L) |

120 |

120 |

120 |

|

Power supply : (Kw) |

30-37 |

37-45 |

37-45 |

The automatic sand supply system uses air pressure to deliver sand from the water knife to the cutting head

Inside the small sand bucket, which reduces the labor intensity of operators, and there is no need to stop the machine when adding sand,

Improved work efficiency and reflected the automation level of CNC water jet knives.

Introducing international advanced technology and designing according to international safety standards, ensuring safety and reliability.

Detail Images

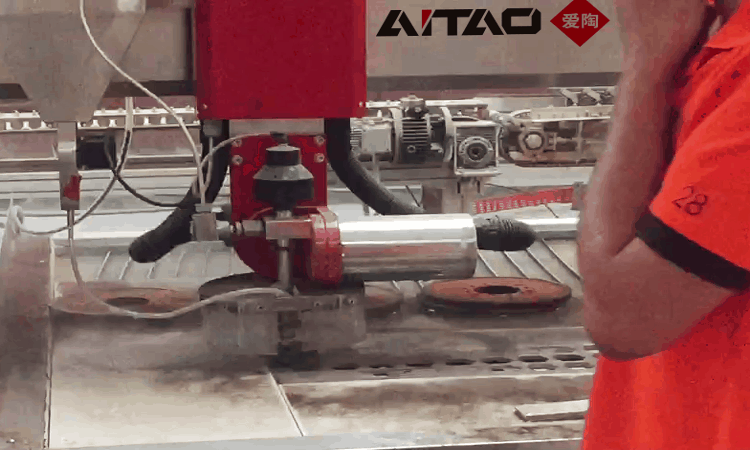

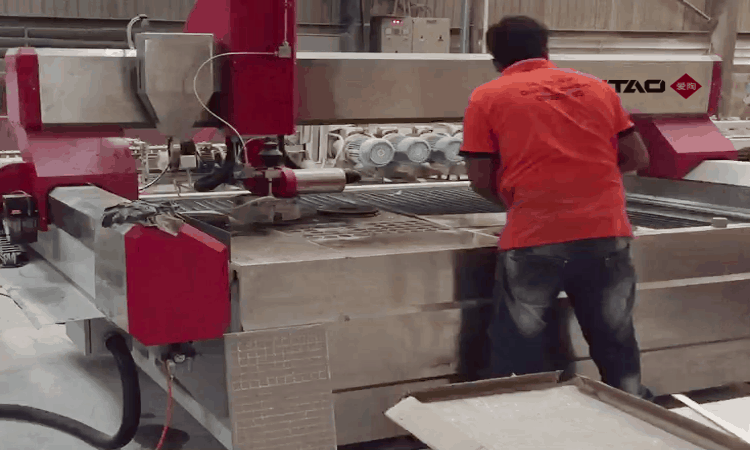

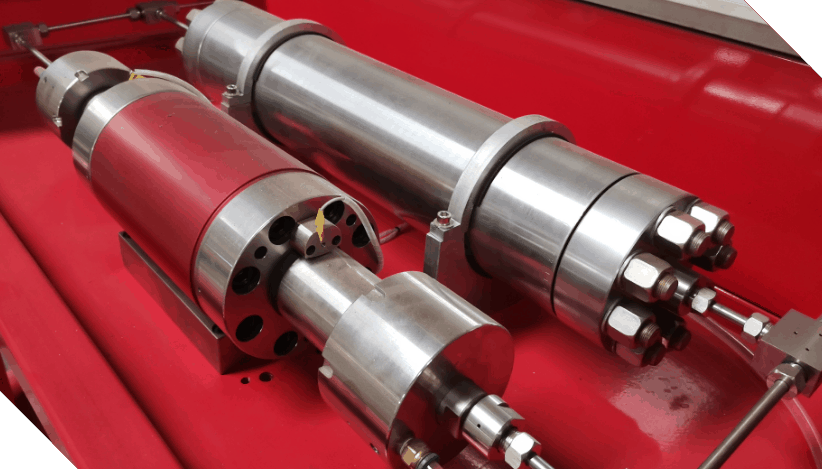

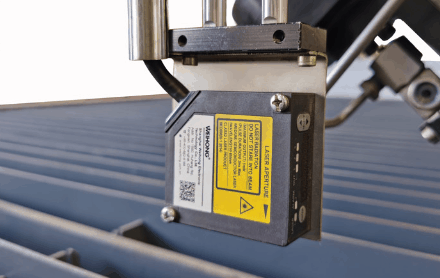

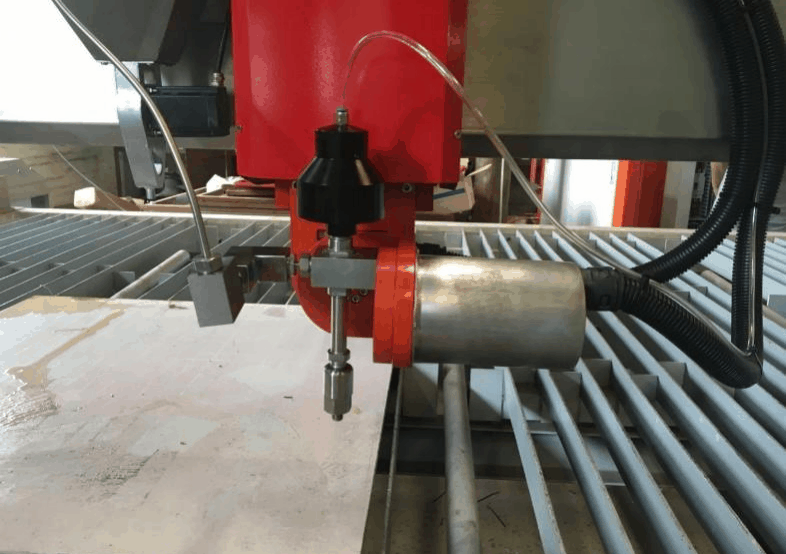

AB Five Axis Cutting System

The Aitao AB five axis cutting water knife easily solves the problem of uneven lower half of the cutting surface affecting assembly quality for the vast stone and ceramic industry. Realize arc plate cutting, cylinder cutting, etc. The cutting head of AB five axis water jet cutter can perform arbitrary curve cutting from 0 to 10 degrees.

Our Service

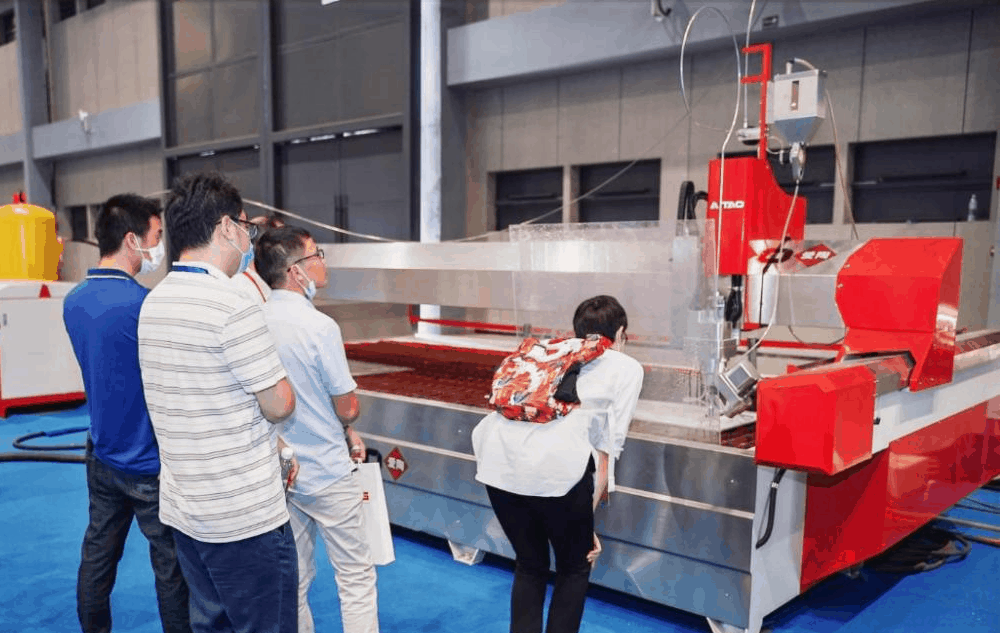

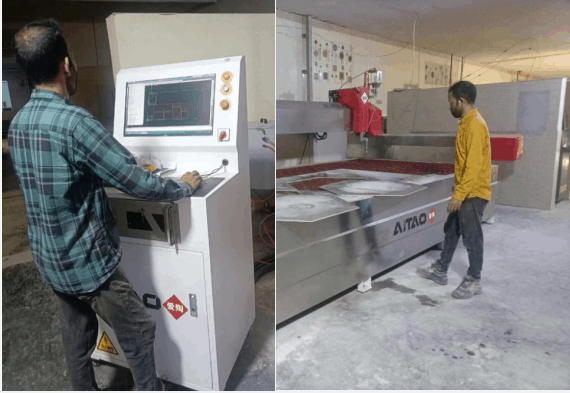

Equipment Cases