Categorys

Hot Product

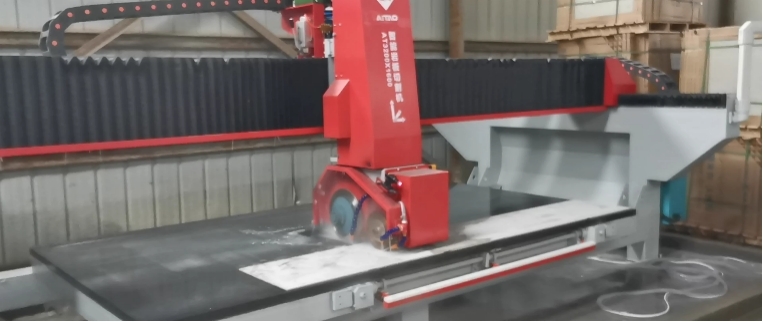

1. With a 90 degree original edge positioning function, it is convenient to retain the original edge for processing the rock slab.

2. Equipped with programming software with one key multi specification continuous cutting function, it is simple and easy to learn.

3. The blade can rotate 90 degrees, allowing for free conversion between longitudinal and transverse cutting.

4. The cutting platform can be vertically flipped up from 0 to 85 degrees, making it convenient for manual loading or aircraft loading, effectively solving the difficulties in processing large plates on conventional aircraft models.

5. The operating system is simple and easy to use, using imported linear guides, ensuring high speed, stability, safety, and reliability.

6. Infrared positioning knife cutting, intuitive and accurate.

7. For sheet cutting, two blades are used to cut without damaging the surface of the rock slab, dropping the bottom, or collapsing the edges.

8. The maximum cutting speed can reach 4.5m/min, resulting in better processing efficiency.

|

Equipment parameters |

|||||

|

Main motor power |

Other motor power |

Moveing speed |

Round-trip shutdown |

revolutions |

Maximum machining size |

|

kw |

kw |

M/min |

/ |

r/min |

mm |

|

15 |

3 |

0.25-4.5 |

Anywhere |

2800-4500 |

3200*2000 |

|

Cutting wheel diameter |

Front and rear motor power |

Head rotation angle |

Total power |

Overall dimensions |

weight |

|

mm |

kw |

° |

kw |

mm |

kg |

|

Φ300-350*50 Φ200-250*30 |

1.5 |

0°~90° |

21.88 |

5300*3000*2300 |

3500 |