Categorys

Hot Product

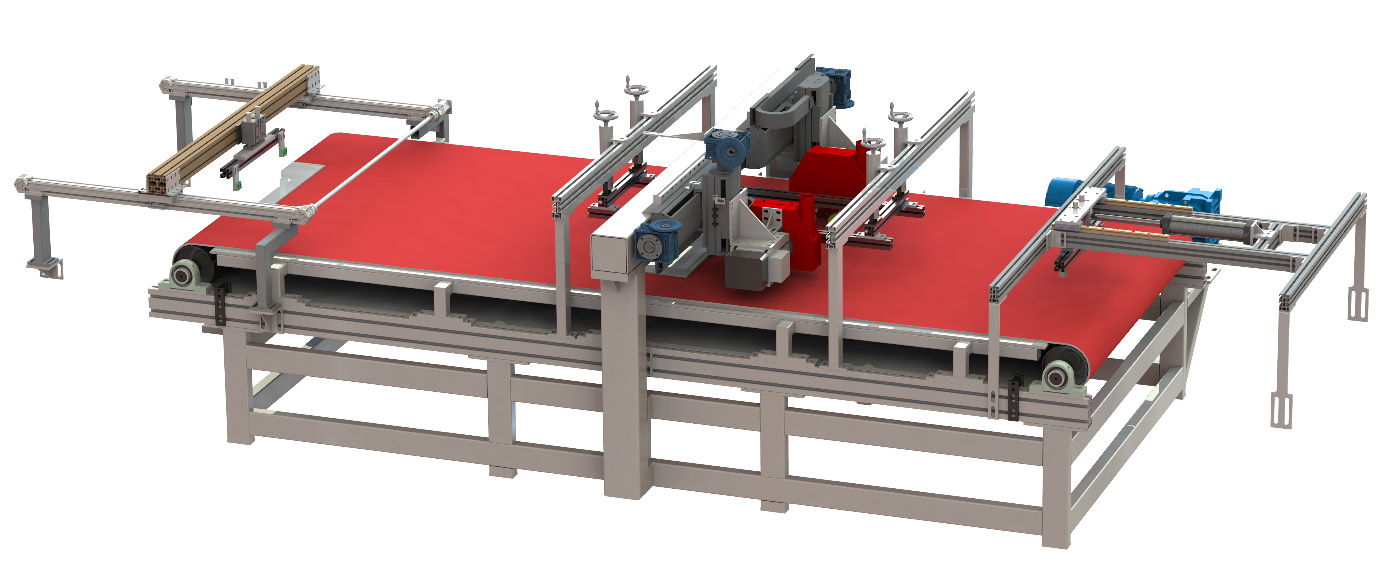

This equipment is used for dry cutting of aluminum oxide thin plates, with automatic lifting

and lowering of left and right widths and cutting heads.

- Working width: 0.6-1.2M adjustable;

- Cutting high-speed motor: Huasong motor 5.5KW-2 sets, at 50HZ, 2800R/MIN;

- Belt motor: CH50-250-3KW (Taibang gear reducer)+Yaskawa variable frequency regulation;

- Knife head lifting motor: Taibang worm gear reducer NMRV050-80.55KW-2 sets;

- Left and right adjustment motors: 2 sets of Taibang worm gear reducers NMRV050-80.55KW-2;

- Cutting speed: 3-6M/MIN adjustable;

- Cutting disc: diameter 230MM (vulnerable parts, one set is randomly delivered. After wear, the buyer will replace it themselves);

- Conveyor belt: W1500 wide, 6+6 belts;

- Compression structure: equipped with manually adjustable compression wheels next to the blade;

- Push plate mechanism: Install a set of push plate mechanisms at the entrance of the cutting machine to prevent the product from entering diagonally

- Pulse bag dust removal

- Number of filter bags: 48; Total filtration area: 24m;

- Gas consumption: 0.37M3/MIN; Equipment (provided by the customer):

- Filter bag wind speed: 1.2-2.0M/mIN. Fan model: 4-72-4A-5.5KW;

- Control system: separate electrical cabinet, 10 inch touch screen control;

- Installed power: 5.5X2+0.55X2+0.55X2+5.5=18.7KW.

- Cutting accuracy: 250 * 1000MM is+0.5MM; 145 * 600mm is+0.25MM

- Cutting capacity: conveyor belt speed ≥ 3M/MIN

- Cutting width: 100MM to 1100MM electrically adjustable

Explanation: This equipment is not a standard customized equipment, and the above

parameters are case parameters. The actual production is subject to the order

requirements