Categorys

Hot Product

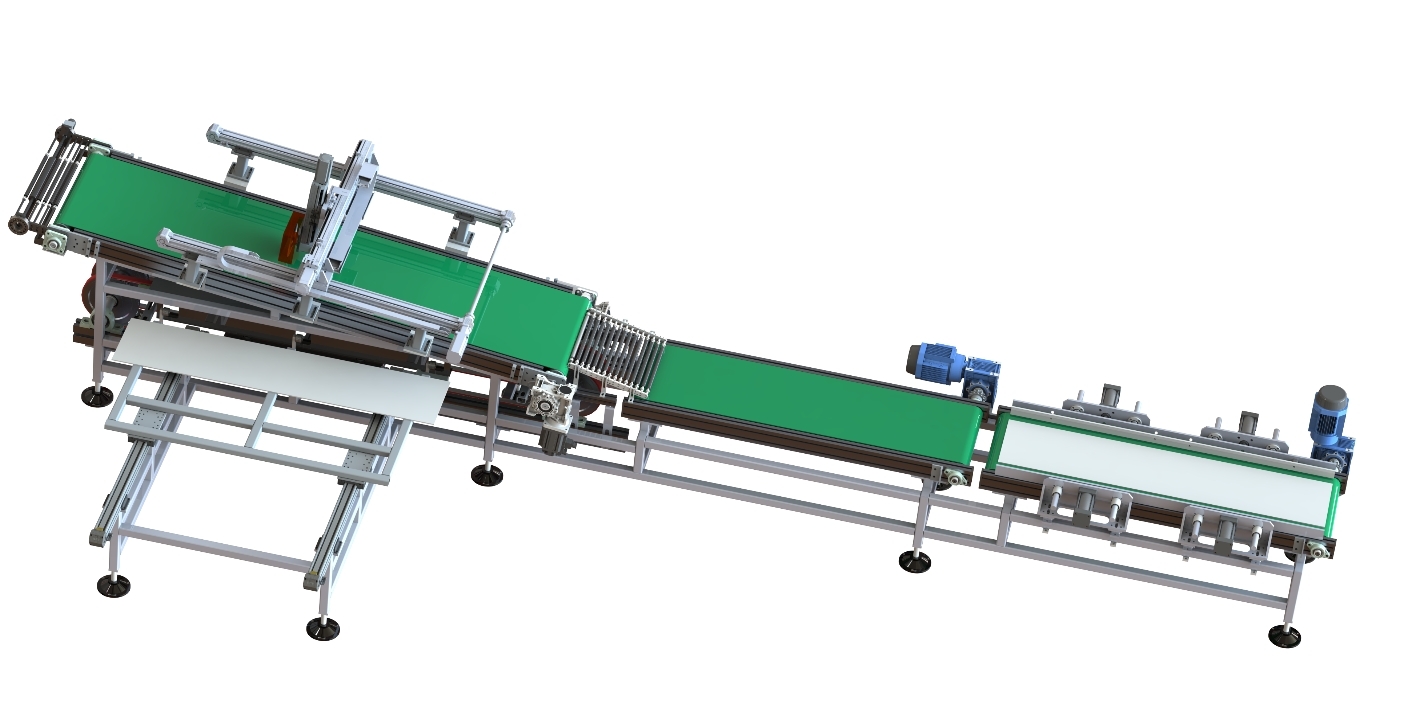

This equipment is used for fixed length cutting of W-shaped ceramic carriers extruded by the extruder;

1. Length: 3.7 meters;

2. In the front section, there are a total of 7 transition rods that can be opened. One end of each rod is equipped with an encoder to collect the extrusion speed feedback to the transmission belt, achieving synchronous transmission;

3. Mid section slope belt: Use a 3mm thick W600 wide flat belt to achieve upper end conveying;

4. Synchronous cutting machine: XYZ three-axis Timing belt module mechanism, X-direction Timing belt is equipped with 400W servo motor, Y-direction Timing belt is equipped with 400W servo motor, Z-direction lifting is equipped with 400W servo motor, and cutter motor is equipped with 750W servo motor;

5. Rear slope: 13 transition rods achieve a smooth transition from the upper belt to the lower belt;

6. Belt drive motor: worm gear reducer NMRV063-30-1.8KW servo motor;

7. Plate feeding drive: Timing belt module is equipped with 400W servo motor drive;

8. Electrical control: All transmissions of the entire machine are controlled by servo motors and servo bus..

Explanation: This equipment is not a standard customized equipment, and the above parameters are case parameters. The actual production is subject to the order requirements.