Categorys

Hot Product

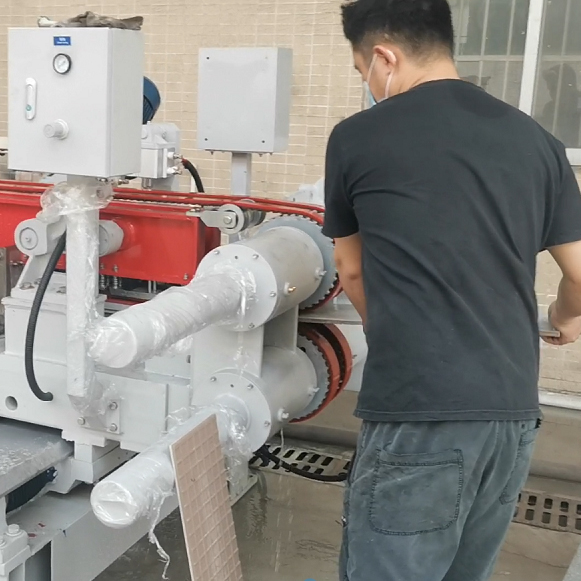

The W450/20+2 belt pressing both sides double belt grinder produced by AITAO can polish and chamfer the edges of tiles, saving time and effort. The machine can work alone or be connected to the production line.

Tile edge grinding and chamfering machine is an indispensable equipment in the field of ceramic processing. Its main function is to carry out accurate edge grinding and chamfering treatment for tiles, so as to improve the beauty and practicability of tiles.

Tile edge grinding and chamfering machines are primarily used for the fine processing of tile edges, involving two main steps: grinding and chamfering. Grinding removes burrs and irregularities from the tile edges, making them smoother; while chamfering makes the corners of the tiles more rounded, reducing safety hazards caused by sharp edges. Through these two processes, tile edge grinding and chamfering machines can significantly enhance both the appearance quality and practicality of tiles.

Tile edge grinding and chamfering machines typically use high-speed rotating grinding heads to grind and chamfer the edges of tiles. The equipment is equipped with a precise transmission system and control system inside, ensuring stability and accuracy in the processing. Additionally, the machine has an automatic adjustment function, which can automatically adjust according to the material and thickness of different tiles, achieving the best processing results.

In the ceramic processing industry, tile edge grinding and chamfering machines play a crucial role. They not only enhance production efficiency but also ensure the quality and aesthetics of tiles. By using this equipment, ceramic processing companies can better meet the market demand for high-quality tiles, boosting product competitiveness.

In addition, the tile grinding corner machine also has high flexibility and versatility, can adapt to different specifications and shapes of tile processing needs. This makes it have a wide application prospect in the ceramic processing industry.

In general, tile grinding and chamfering machine is one of the important equipment in the ceramic processing industry. It improves the beauty and practicability of tiles through accurate grinding and chamfering treatment, bringing significant benefits to ceramic processing enterprises.

[parameter]

Working width: 150-450mm

Conveyor belt speed: 14-42 m/min

Size: 6940*2090*1940mm

Function: edge grinding and polishing, chamfering

Control: CNC panel control

Load tile mode: manual (can be equipped with transmission device, connected to the production line)

Working conditions: water cooling

Number of grinding heads: 20 Top chamfer,

Number of chamfer heads: 2

Strip type structure, specification: AT20*38

Double conveyor belt, specification: AT20*50mm

The main drive adopts variable frequency speed control, installed power: 7.5Kw

Total success rate of edge grinding: 20*5.5Kw

The working width is electrically adjustable, with a power of 0.55Kw

Total power: 118Kw